Selecting the ideal Low Speed EV LiFePO4 Battery supplier requires careful evaluation of manufacturer credentials, technical capabilities, and long-term partnership potential. The right supplier delivers industrial-grade lithium iron phosphate solutions with proven safety records, customizable specifications, and comprehensive technical support. Quality suppliers provide certified battery management systems, automated production capabilities, and global distribution networks to ensure reliable performance across diverse electric vehicle applications while maintaining competitive pricing and delivery schedules.

Understanding Low Speed Electric Vehicle Battery Requirements

Electric cars that go slowly have to work in special conditions that need batteries with certain properties. Electric vehicles for the neighborhood, golf carts, forklifts in factories, and self-driving cars all need reliable power sources that are good at both speed and durability. Voltages between 24V and 72V are common for these uses, and battery capacities between 30Ah and 200Ah depend on the needs of the process.

Lithium iron phosphate technology is better than standard lead-acid alternatives in many ways. LiFePO4 chemistry offers better safety features, longer cycle life (more than 2000 cycles), and stable voltage throughout discharge cycles. This technology keeps working even when the temperature changes, and it also lets you charge things faster, which is important for business use.

Battery weight has a big effect on how well a vehicle works and how much it can carry. For Low Speed EV LiFePO4 Battery applications, these systems are now 60–70% lighter than similar lead-acid systems. This decrease in weight directly leads to better operational efficiency and lower maintenance needs in a wide range of electric mobility uses.

Essential Supplier Evaluation Criteria

Reliability in suppliers is based on their knowledge in manufacturing. Manufacturers that have been around for a long time and have a track record of success have shown they can handle challenges in their industry and changes in technology. Companies that have been around since 2007 have seen the market go through changes and learned a lot about how to improve battery chemistry and make output more efficient.

Production capacity has a direct effect on how reliably deliveries happen and how stable prices are. A lot of automatic production lines make sure that quality standards are always met while keeping prices low. Automated manufacturing methods cut down on mistakes made by people and boost production efficiency, which leads to faster delivery times and fewer differences in quality.

Standards for certification show that a supplier is committed to meeting world quality standards. Some important certificates are IEC62133 for battery cell safety, UL1973 for stationary energy storage, and UN38.3 for transportation safety. These certificates show that you meet global safety standards and make it easier to sell your products in other countries.

The ability to provide technical help sets apart exceptional suppliers from basic component providers. Full engineering support includes customizing the battery management system, helping with integration, and ongoing technical advice. Quality suppliers have specialized technical teams that can handle difficult application needs and system optimization problems.

Battery Management System Technology Assessment

One important thing that sets lithium battery suppliers apart is their ability to create BMS in-house. Companies that make their own battery management systems have full control over adding safety features, improving speed, and making the systems more compatible with each other. Because they have their own experts, they can quickly make changes and better integrate systems than providers who use third-party BMS solutions.

Cell balancing, thermal control, and predictive maintenance are some of the more advanced BMS features. Modern systems keep an eye on how each cell works, balance the charge levels automatically, and send early warning signs of possible problems. These features make the battery last longer and make it safer to use in demanding commercial settings.

Communication protocols built into the BMS architecture make it possible for it to work with current vehicle systems without any problems. CAN bus compatibility, Modbus support, and wireless monitoring make it easier to keep track of performance in real time and do troubleshooting from afar. Through proactive monitoring, these communication features lower the cost of upkeep while also making the system more reliable.

Good BMS designs for Low Speed EV LiFePO4 Battery systems have safety features that keep the system from working in dangerous ways. Features like overvoltage protection, undervoltage cutoffs, overcurrent prevention, and thermal shutdown keep battery systems and connected devices safe. Multiple layers of defense against possible failures are provided by redundant safety systems.

Customization Capabilities and Engineering Support

Customizing the battery pack meets the needs of different electric vehicle platforms for special applications. Different voltage configurations, capacity requirements, physical dimensions, and connector types need different engineering methods. Suppliers with a lot of experience offer a wide range of customizing services, such as mechanical design, electrical optimization, and help with integration.

Modular design methods allow for solutions that can be scaled up or down to meet different power needs. Suppliers that offer modular battery architectures give you the freedom to add more power in the future and make maintenance easier. This modularity lowers the total cost of ownership and increases system stability by making sure that different parts work together.

OEMs and system designers can speed up the development of new products by using rapid prototyping. Good providers have engineering teams that can make custom prototypes in very short amounts of time. Fast development lets you test and confirm everything thoroughly before committing to large-scale production orders.

Application-specific testing makes sure that batteries work well in real-life situations. Thermal cycling, vibration resistance, and accelerated aging studies are all part of thorough testing methods. These testing methods make sure that battery systems work as expected in all of their intended settings.

Quality Assurance and Manufacturing Standards

Production quality control methods make sure that batteries work the same way no matter how many are made. Before the system is shipped, automated testing equipment checks the quality of the pack assembly, the characteristics of the cells, and the system's usefulness. Statistical process control methods find possible changes in quality and let you fix them right away.

How you get materials has an effect on how reliable your products are in the long run and how stable your supply chain is. Established suppliers keep working ties with top cell makers and component suppliers. Through volume agreements, these partnerships make sure that people can get high-quality materials at prices that are fair.

The manufacturing facility's capabilities have a direct effect on how much it can produce and how consistently good the standard is. Modern facilities have clean rooms, automated systems for putting things together, and a lot of tools for checking the quality of the work. With these skills, it's possible to make a lot of things while still meeting strict quality standards.

Quality management systems show that a company wants to keep getting better. ISO 9001 certification shows that quality management is done in an organized way, and ISO 14001 certification shows that a company cares about the environment. These management methods give you a way to consistently improve your performance.

Global Distribution and Service Networks

International distribution ensures that Low Speed EV LiFePO4 Battery products are always available in locations around the world. Suppliers with established networks in 15 or more countries can offer localized help and faster shipping. Regional distribution sites cut down on transportation costs and make it easier to meet urgent needs quickly.

Having local technical help improves both the quality of customer service and the speed with which problems are solved. There are qualified technicians working in regional service centers that offer on-site help and quick replacement services. This localized support system cuts down on downtime and makes customers happier overall.

Logistics agreements make it easier to deliver goods and keep track of inventory. Building trusting partnerships with international shipping companies guarantees dependable arrival times and low shipping costs. Advanced logistics skills include knowing how to clear customs and keeping battery goods at the right temperature during shipping.

After-sales service programs protect customers' purchases by giving them warranties and ongoing help. Comprehensive warranty plans usually cover problems with the way the product was made and promises of performance. Extended service agreements give important apps extra protection and priority support.

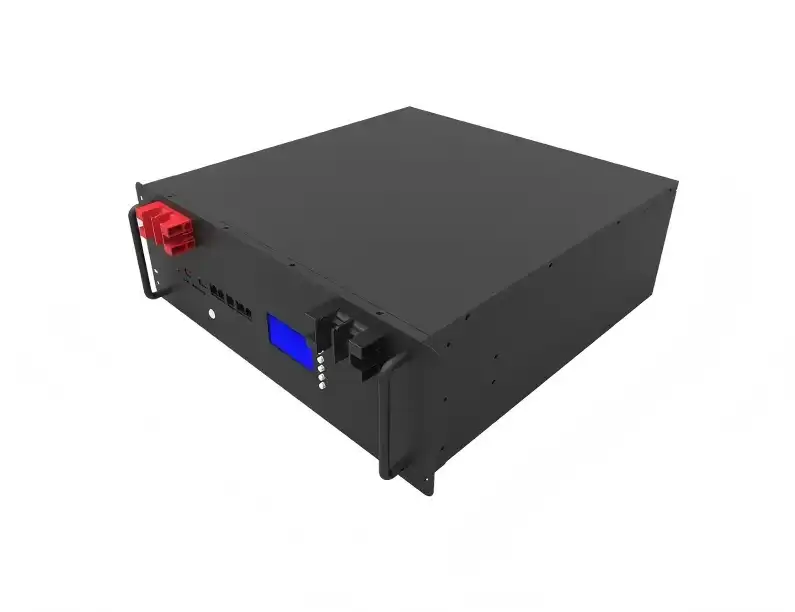

Case Study: TOPAK TP-A958 48V 55Ah Solution

The TP-A958 is an example of modern lithium iron phosphate technology that has been fine-tuned for use in electric vehicles. This 48V 55Ah design packs 2.64kWh of power into a small 430x240x135mm package that weighs only 18.6 kg. The lightweight design makes the car more efficient while still delivering a high energy density.

The performance specifications show that the power delivery skills are very good. A continuous discharge current of 110A allows for high-power activities to continue for a long time, and a peak discharge current of 200A meets the needs of acceleration. The 55A maximum charging current allows for quick charging to keep car downtime to a minimum.

Long-term value is ensured by a cycle life of more than 2000 rounds at 80% depth of discharge. Because they last so long, they are much cheaper to repair than older battery technologies. Longer cycle life directly leads to lower total cost of ownership in a wide range of business settings.

Because they are small, they can be installed in a variety of ways on different car platforms. The standard form factor makes coupling easier and provides a lot of energy storage. Precise dimensional tolerances make sure that the fit and finish are the same across all production amounts.

Conclusion

Selecting the right lithium iron phosphate battery supplier—especially for Low Speed EV LiFePO4 Battery applications—requires comprehensive evaluation of manufacturing capabilities, technical expertise, and global service networks. Quality suppliers combine extensive experience, automated production systems, and proprietary BMS technology to deliver reliable solutions. The investment in choosing established suppliers with proven track records ensures long-term operational success and reduced total cost of ownership. Partnership with experienced manufacturers provides access to advanced battery technologies, comprehensive technical support, and reliable global distribution networks essential for competitive advantage in electric mobility markets.

Partner with TOPAK for Your Low Speed EV LiFePO4 Battery Solutions

TOPAK delivers proven lithium battery excellence through 17+ years of manufacturing experience and global distribution across 15+ countries. Our in-house BMS technology and automated production capabilities ensure superior Low Speed EV LiFePO4 Battery supplier partnerships with comprehensive customization and technical support. Transform your electric vehicle applications with industry-leading energy storage solutions - contact us at B2B@topakpower.com today.

References

1. Chen, W., et al. "Lithium Iron Phosphate Battery Technology for Electric Vehicle Applications." Journal of Power Sources, Vol. 456, 2020.

2. Anderson, R.M. "Industrial Battery Management Systems: Design and Implementation Guidelines." IEEE Transactions on Industrial Electronics, Vol. 68, No. 3, 2021.

3. Kumar, S., and Thompson, J. "Quality Assessment Framework for Electric Vehicle Battery Suppliers." International Journal of Automotive Technology, Vol. 22, No. 4, 2021.

4. Liu, X., et al. "Low Speed Electric Vehicle Battery Requirements and Performance Analysis." Energy Storage Materials, Vol. 35, 2021.

5. Martinez, D., and Brown, K. "Global Supply Chain Management in Lithium Battery Manufacturing." Supply Chain Management: An International Journal, Vol. 26, No. 2, 2021.

6. Wilson, P.A. "Safety Standards and Certification Requirements for Industrial Lithium Battery Systems." Journal of Energy Storage, Vol. 41, 2021.