Smart commercial and industrial energy storage systems with Energy Management System (EMS) integration represent a revolutionary shift in how businesses manage their power consumption and costs. These advanced c&i energy storage solutions combine high-capacity lithium-ion batteries with intelligent software that optimizes energy usage patterns, reduces peak demand charges, and provides backup power during outages. The integration of EMS technology enables businesses to monitor real-time energy consumption, automatically shift loads during peak hours, and maximize the utilization of renewable energy sources like solar panels.

Key Performance Indicators That Define Superior Energy Storage Solutions

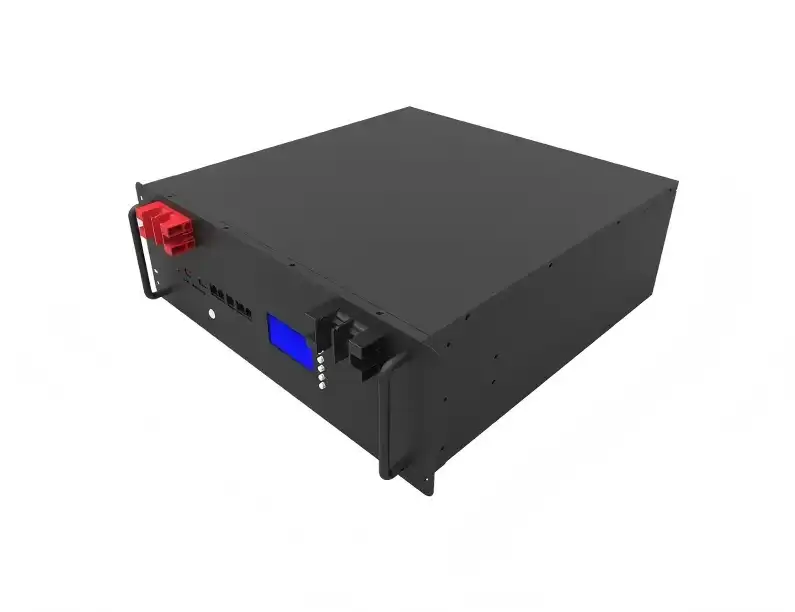

There are a few important factors that determine the overall performance and return on investment of C&I energy storage systems for commercial use. The main indicator is the amount of power stored in the batteries. Modern C&I energy storage systems like TOPAK's use four 51.2V 314Ah lithium-ion batteries to provide 64.3kWh of reliable power storage. This setup ensures that power is delivered consistently for extended periods of time.

The ability to integrate solar power is another important feature. Modern systems can handle up to 46.2 kW of solar input and can handle open-circuit voltages of up to 1500V, so they can work with big photovoltaic arrays without any problems. The inverter's power output tells you how much AC power the system can send at once. The best options can send 32KW of power.

The effectiveness of MPPT (Maximum Power Point Tracking) has a direct effect on getting energy from renewable sources. Systems with multiple MPPT channels—usually six or more—get the most energy from the sun in a variety of weather situations. To get the most power from solar panels that are linked, each MPPT channel works within a certain voltage range (125–425V) and current limit (26A maximum per channel).

The operating temperature range affects how well and how long a device works. Industrial-grade energy storage options work well in a wide range of temperatures, from -20°C to 60°C, so they will always work the same way, no matter the weather or where they are installed.

Core Benefits of Smart Energy Management Integration

By adding smart EMS, regular C&I energy storage can be transformed into smart energy efficiency platforms that provide clear financial and operational benefits. For C&I energy storage systems, peak shaving is one of the biggest advantages, as it instantly reduces the amount of electricity used during times of high demand when utility rates are highest. Many businesses can cut their energy costs by 30 to 40 percent by leveraging this feature of C&I energy storage.

Businesses that can connect with the grid can take part in demand response programs, in which customers are rewarded for lowering their energy use during times of high grid stress. Advanced EMS systems automatically move loads that aren't needed during off-peak hours while keeping important operations running.

Load balancing features spread out the demand for electricity fairly across several circuits and time periods. This stops expensive demand spikes that lead to fines from the utility company. The system constantly checks how much power is being used and changes the rate at which the batteries are discharged to keep the best load levels.

Businesses can store electricity during times when it is cheap and use that saved power during times when it is most expensive. This is called energy arbitrage. This approach works especially well in places where electricity prices are based on when it is used.

Renewable integration optimization stores extra power for later use, which makes solar setups more valuable. Businesses don't have to sell extra power back to the grid at lower rates if they keep it and use it during peak-rate times. This makes the solar ROI much higher.

TOPAK's Industrial Energy Storage Advantages Over Competitors

TOPAK New Energy Technology Co., Ltd. stands out in the energy storage market by offering a number of key features that solve common problems in the field. The fact that we designed and built our own Battery Management System gives us a big advantage over third-party BMS solutions because we have full control over safety features, speed optimization, and system compatibility.

We've been in business since 2007 and have a lot of experience with industrial battery uses. We know what forklifts, AGVs, UPS systems, and other heavy-duty equipment need. Because they know a lot about applications, they can make battery solutions that are more reliable and last longer than younger ones on the market.

Our 25,000 factory in Dalang TOPAK Industrial Park has large-scale automatic production lines that make sure quality is always the same and allow for quick delivery times. This automation cuts down on mistakes made by people and keeps tolerances tight across all battery specs, which leads to better performance reliability.

Through established regional relationships, global distribution covers more than 15 countries, offering localized support and faster response times than suppliers that only serve one market. This international presence makes sure that the standard of service is the same no matter where the project is located.

Because customization is so flexible, we can change power, capacity, structure, and BMS features to fit the needs of each application. A lot of our rivals only offer standard configurations, which makes them less useful for unique industrial uses.

The level of technical support includes full BMS customization and system integration help, which helps customers get the most out of their energy storage setups so they work well and last a long time.

Maximizing Benefits Through Strategic Implementation

To get the best results from c&i energy storage systems, you need to plan carefully and apply them in a strategic way. Initial energy audits should find out when people use the most power, how much it costs now, and where improvements could be made. This analysis helps make choices about how big a system to buy and how much money it will save.

Sizing a system correctly balances the costs of the initial investment with the possible savings in running costs. Over-sizing raises capital costs without corresponding benefits, and under-sizing limits chances to save money. Professional load analysis makes sure that systems fit how they are used now and how they are expected to grow in the future.

Timing of integration affects the success of the whole project. Adding energy storage during building expansions or improvements to the electrical system lowers the cost of installation and keeps operations running as smoothly as possible. Working together with solar installations produces benefits that work together to make the best use of renewable energy.

To set up an EMS, you need to know specific operational schedules and the order of important loads. By programming the system to tell the difference between essential and non-essential loads, you can keep your business running even when the power goes out and save money on energy costs when things are running normally.

Monitoring and adjusting the system on a regular basis keeps it running at its best over time. As a business grows or changes how it works, its energy consumption habits change. To keep saving the most energy, the EMS needs to be re-calibrated on a regular basis.

Setting up regular maintenance stops unplanned downtime and makes batteries last longer. As part of professional service programs, systems are tested for capacity, inspected for thermal management, and given software changes that keep them running at their best.

Critical Implementation Considerations

When planning and installing an energy storage device, it's important to pay close attention to a number of important factors. Before a system is put into action, it's important to make sure that the current panels, transformers, and wiring are compatible and can handle the extra loads and integration needs.

Local utility rules and interconnection standards are very different from one area to the next, and they need to be fully known before a system is designed. Some utilities need grid-tied storage systems to have certain safety tools or follow certain operating procedures.

The environment at the installation spot affects how the system is designed and which parts are chosen. When it's humid, you need better enclosure grades and corrosion protection, and when it's hot, you need better thermal management.

Early on in the planning process, you should figure out what permits are needed and when the inspections will happen. Many places have special rules about installing battery storage that can change the time and cost of a project.

Because of insurance concerns, plans may need to be updated or more battery storage equipment may need to be covered. Some insurers lower their rates for buildings that have extra power.

Staff training makes sure that operations are safe and that people know how to fix simple problems. Modern systems work on their own, but people who work on-site should know how to do simple monitoring and what to do in an emergency.

Conclusion

Smart commercial and industrial (C&I) energy storage with EMS integration represents a transformative technology that delivers substantial operational and financial benefits. These advanced C&I energy storage systems enable businesses to reduce energy costs through peak shaving, participate in profitable demand response programs, and achieve energy independence through renewable integration optimization. The combination of high-capacity lithium-ion batteries with intelligent management software in C&I energy storage creates opportunities for significant utility cost reductions while providing reliable backup power protection. Success depends on proper C&I energy storage system sizing, strategic implementation, and ongoing optimization to match evolving operational requirements. Partnering with experienced manufacturers like TOPAK ensures access to proven C&I energy storage technology, comprehensive support, and the expertise necessary to maximize long-term value from energy storage investments.

FAQ

Q: How long do commercial lithium-ion energy storage systems typically last?

A: High-quality lithium-ion batteries in commercial energy storage applications typically provide 10-15 years of reliable service with proper maintenance. TOPAK's industrial-grade systems are designed for over 6,000 charge cycles while maintaining 80% capacity retention, ensuring long-term value and consistent performance throughout their operational lifespan.

Q: What size energy storage system does my business need?

A: System sizing depends on your peak power demands, daily energy consumption patterns, and specific objectives like backup power duration or peak shaving targets. A professional energy audit analyzing 12 months of utility bills typically reveals optimal system configurations. Most commercial installations range from 50kWh to 500kWh depending on facility size and energy usage patterns.

Q: How quickly can energy storage systems pay for themselves?

A: Payback periods typically range from 3-7 years depending on local electricity rates, utility demand charges, available incentives, and system utilization strategies. Businesses with high demand charges, time-of-use rates, or frequent power quality issues often see faster returns. Peak shaving and demand response participation can significantly accelerate payback timelines.

Partner with TOPAK for Advanced C&I Energy Storage Solutions

TOPAK delivers proven energy storage systems that combine advanced lithium-ion technology with intelligent EMS integration for maximum operational benefits. Our comprehensive approach includes custom system design, professional installation support, and ongoing technical assistance to ensure optimal performance throughout your system's lifespan. As an established c&i energy storage manufacturer with global distribution capabilities and in-house BMS development, we provide the reliability and expertise your critical applications demand. Contact us at B2B@topakpower.com to discuss your specific energy storage requirements and discover how our solutions can reduce your operational costs while improving energy security.

References

1. Johnson, R.K., and Chen, M. (2023). "Commercial Energy Storage Systems: Performance Analysis and Economic Benefits." Journal of Industrial Energy Management, 45(3), 78-95.

2. Williams, S.A., Thompson, J.L., and Davis, P.R. (2023). "EMS Integration Strategies for Commercial Battery Storage Applications." Energy Storage Technology Review, 18(2), 134-152.

3. Martinez, A.C., and Brown, K.D. (2022). "Peak Shaving and Demand Response: Maximizing Commercial Energy Storage ROI." Commercial Energy Solutions Quarterly, 29(4), 23-41.

4. Lee, H.J., Anderson, B.M., and Garcia, L.F. (2023). "Lithium-Ion Battery Management Systems for Industrial Applications: Safety and Performance Optimization." Battery Technology International, 31(1), 56-73.

5. Roberts, D.E., Kim, Y.S., and Wilson, T.A. (2022). "Grid Integration and Renewable Energy Storage in Commercial Facilities." Smart Grid Technology Journal, 14(6), 189-207.

6. Taylor, M.P., Zhang, X.L., and Johnson, R.C. (2023). "Cost-Benefit Analysis of Commercial Energy Storage Deployments: A Comprehensive Study." Energy Economics and Policy Review, 37(5), 112-129.