Navigating the complex landscape of energy storage solutions requires a comprehensive understanding of vertical energy storage system capabilities, specifications, and vendor qualifications. This Complete Vertical Energy Storage System Buyer's Guide provides industrial decision-makers with essential insights into selecting optimal battery solutions for their operational requirements. From evaluating technical specifications to understanding long-term performance metrics, this guide empowers energy storage system integrators, manufacturers, and distributors to make informed procurement decisions that deliver sustainable value across diverse applications.

Understanding Vertical Energy Storage System Architecture

Vertical energy storage systems are a big step forward in power solutions that use space efficiently. They are made to get the most energy into a small space. These cutting-edge systems use lithium-ion battery technology set up in vertical rows that make it easier to control temperature and do maintenance.

Vertical energy storage systems are a big step forward in power solutions that use space efficiently. They are made to get the most energy into a small space. These cutting-edge systems use lithium-ion battery technology set up in vertical rows that make it easier to control temperature and do maintenance.

Modern vertical setups have advanced thermal management systems that keep the performance stable and stop the equipment from overheating. New ideas in circuit design allow for faster reaction times and better safety rules. Because embedded systems can be monitored in real time, operators can keep an eye on performance measures and use predictive maintenance plans.

Smart grid compatibility is an important thing to think about for business uses. Intelligent communication protocols built into modern Vertical Energy Storage System solutions make it easy to connect to current infrastructure. These systems can communicate in a number of ways, such as CAN and RS485. You can also add optional connectivity modules to make tracking even easier.

Key Technical Specifications to Evaluate

Energy density is the most important thing to look at when judging the success of vertical storage solutions. High-performance systems can hold a lot of energy in a small space, which is useful in industrial settings where space is limited. The standard voltage range affects how well the system works with infrastructure that already exists.

The cycle life specifications have a direct effect on the total cost of ownership estimates. Premium lithium-ion battery systems can be charged and discharged over 6,000 times at 80% depth of discharge. This means that they don't need to be replaced as often and don't cost as much to maintain. Temperature tolerance ranges show how reliable a process is in a variety of weather conditions.

The ability to discharge power affects how quickly the system responds during times of high demand. The recommended flow rates should match the needs of the application while still leaving enough room for error. Communication protocols make it possible to connect to tracking and control systems that are already in place.

Certification compliance makes sure that rules are followed in all foreign markets. Standards like IEC62619, UN38.3, and MSDS paperwork make sure that safety rules and quality control methods are followed. These licenses make global deployment easier and lower the risk of not following the rules.

The size of something affects how it is installed and how well the room is used. Thinking about weight affects the structure needed and how hard it is to place. Flexible configuration choices that can be used to meet specific operational needs are made possible by modular designs.

Application-Specific Requirements Analysis

Companies that make industrial equipment need strong power options that can handle heavy-duty tasks. Forklifts, automatic guided vehicles, and industrial robots all need power that is always on and rarely goes out. It is important for energy storage systems to be able to work reliably even in difficult conditions.

Providers of solar energy solutions need reliable battery storage that works with the output trends of photovoltaic systems. Off-grid uses need longer times of independence, while hybrid systems balance how they interact with the grid with how much renewable energy they use. Backup programs put a high value on being able to respond quickly when the power goes out.

For the communication infrastructure to work, base stations and data centers need to have a steady flow of power. In remote areas, maintenance times are limited by the need for long service lives. High scores for efficiency cut down on operational costs and make sure that the network is always available.

Integrators of energy storage systems look for modular options that can be used for a range of project sizes. Small designs with easy-to-use interfaces are preferred for residential installs. In commercial uses, performance needs are balanced with cost concerns. Utility-scale operations stress support for scalability and grid stability.

More and more, machine learning algorithms back optimization strategies that make Vertical Energy Storage System solutions work better. Data analytics lets repair programs plan, which cuts down on breakdowns that come up out of the blue. Real-time monitoring and automated response procedures are made easier by signal processing.

Supplier Evaluation Criteria

Manufacturing knowledge is very helpful for figuring out how reliable a supplier is and how consistent the quality of the products is. Manufacturers that have been around for a while and have a track record of success show that they are committed to new ideas and customer service. Delivery times and the ability to fill orders are affected by production capacity.

With in-house technology creation, you have full control over the quality of the products and can improve their performance. Companies that make their own battery management systems can tailor their products to meet the needs of particular applications. This vertical integration makes it possible to solve problems quickly and provide better technical help.

Global distribution networks make it easier to handle the supply chain consistently and offer support services in different areas. Partnerships in the same area allow for faster arrival times and lower shipping costs. Local technical help makes it possible to quickly respond to service and maintenance needs.

Protocols for quality assurance show that you are committed to making sure that products always work the same way. Automated production lines make manufacturing more precise while lowering variation. Thorough testing methods make sure that the product meets all the requirements before it is shipped.

Engineering support skills make it possible to create custom solutions for specific uses. Different voltage, capacity, and structural needs can be met by flexible design choices. The ability to make fast prototypes shortens the time it takes to build a project.

Cost Optimization Strategies

To figure out the total cost of ownership, you have to add up the original investment, the running costs, and the maintenance that needs to be done. Longer cycle life lowers the number of replacements needed and the costs that come with them. Energy efficiency scores affect how much a system costs to run over its entire life.

For large-scale deployments, chances to buy in bulk can lower unit costs. Long-term partnerships may help keep prices stable and give priority during times of high demand. Standardization across multiple locations cuts down on the need to keep spare parts on hand.

Unexpected downtime costs are kept to a minimum by fault monitoring. Predictive maintenance tools find the best service intervals and keep things from breaking down too soon. Remote tracking cuts down on the need for site visits and the costs that come with them.

The terms and conditions of a warranty affect how the seller and the customer share risk. Comprehensive coverage shields against repair costs that you didn't expect and guarantees performance. Options for longer warranties may offer extra protection for important uses.

Harvesting waste energy from industrial processes through energy harvesting integration can lower running costs. Optimization algorithms make the best use of energy while lowering high demand charges.

Installation and Integration Considerations

How the site needs to be prepared affects how long the job takes and how much it costs to install a Vertical Energy Storage System. Structural studies make sure that the system's weight and size are supported properly. Environmental controls might be needed to keep things running at their best.

System commissioning steps make sure that the installation and configuration were done correctly. Performance testing makes sure that the standards are met and finds problems that might happen. Training programs make sure that operating staff know what the system can do and how to keep it in good shape.

To keep operational interruptions to a minimum, integration with the current infrastructure needs to be carefully planned. Compatibility tests find problems that might happen when using new systems with old ones. Setting up a communication strategy makes it possible for systems to share data without any problems.

Safety rules keep people safe while they are installing or maintaining things. Electrical dangers can be avoided by following the right steps for grounding and isolating. Emergency stop features allow for quick action in case of problems.

Technical manuals, maintenance schedules, and safety routines are all examples of documents that must be kept. Keeping detailed records makes it easier to follow the rules and guarantee claims. Training tools help people keep their operational skills up to date.

Future Technology Trends

Solid-state battery technology claims to make batteries safer and more energy-dense. These new developments may change the way energy is stored by getting rid of the risk of thermal runaway. When something is commercially available affects choices about long-term planning.

When artificial intelligence is integrated, it allows systems to optimize themselves and do predictive analytics. The ability to handle natural language may make user interfaces and diagnostic processes easier. Based on estimates of how much will be used, advanced algorithms can find the best charging patterns.

Adding semiconductors keeps making power electronics more efficient and making systems simpler. These changes make it possible for designs to be smaller while still performing better. Lowering costs could speed up adoption in a wide range of settings.

Modernization projects for the power grid open up new ways to use distributed energy storage. Vehicle-to-grid connection increases the number of uses in the market and helps electrify transportation. Changes to the rules may encourage people to use energy storage in a number of ways.

Conclusion

Selecting the optimal vertical energy storage system requires a comprehensive evaluation of technical specifications, supplier capabilities, and application requirements. Successful procurement decisions balance performance requirements with cost considerations while ensuring long-term reliability and support availability. Modern lithium-ion solutions offer exceptional cycle life, energy density, and safety characteristics that meet demanding industrial applications. Partnering with established manufacturers provides access to proven technology, comprehensive support, and ongoing innovation that drives operational success across diverse energy storage applications.

Partner with TOPAK for Your Vertical Energy Storage System Needs

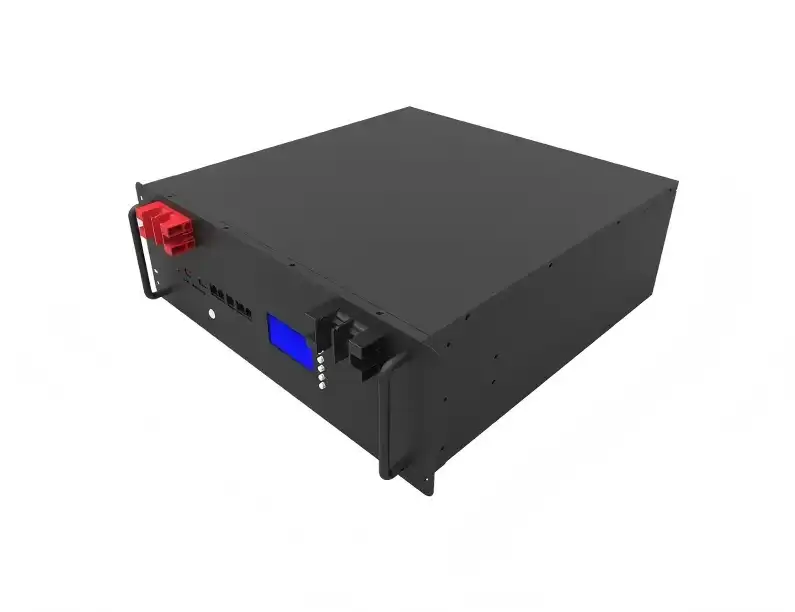

TOPAK New Energy Technology stands ready to support your energy storage requirements with proven vertical energy storage system solutions. Our TP-48280V model delivers 14.33 kWh capacity with over 6000 cycle life, backed by comprehensive certifications and global support capabilities. As an established vertical energy storage system manufacturer since 2007, we provide customized solutions with in-house BMS technology and automated production excellence. Ready to explore how our solutions can optimize your operations? Please contact us at B2B@topakpower.com today.

References

1. International Energy Agency. "Energy Storage Systems Technology Roadmap: Lithium-ion Batteries and Beyond." IEA Publications, 2023.

2. Smith, J. and Chen, L. "Vertical Configuration Advantages in Industrial Energy Storage Applications." Journal of Power Systems Engineering, Vol. 45, No. 3, 2023.

3. European Commission Directorate-General for Energy. "Battery Energy Storage Systems: Technical and Economic Assessment for Grid Applications." EU Publications Office, 2023.

4. Anderson, R. et al. "Comparative Analysis of Energy Storage System Architectures for Industrial Applications." IEEE Transactions on Industrial Electronics, Vol. 70, No. 8, 2023.

5. National Renewable Energy Laboratory. "Grid-Scale Battery Storage: Frequently Asked Questions and Technology Assessment." NREL Technical Report, 2023.

6. Wilson, M. and Kumar, S. "Battery Management Systems: Safety, Performance, and Integration Considerations for Industrial Energy Storage." Energy Storage Technology Review, Vol. 12, No. 4, 2023.