Selecting the right low speed vehicle batteries can significantly impact your equipment's performance, operational costs, and maintenance requirements. Whether you're purchasing for golf carts, utility vehicles, or industrial applications, understanding battery technology, capacity requirements, and safety features becomes crucial for making informed decisions. This comprehensive guide covers everything from battery chemistry comparisons to lifecycle considerations, helping you navigate the complex landscape of electric vehicle power solutions. Smart battery selection not only enhances vehicle performance but also reduces long-term operational expenses through improved durability and efficiency.

Understanding Battery Chemistry Options for Low Speed Vehicles

There are two main types of batteries used in modern electric vehicles: lithium-ion and lead-acid. If you need to meet specific application needs and budget limits, each chemistry has distinctive benefits.

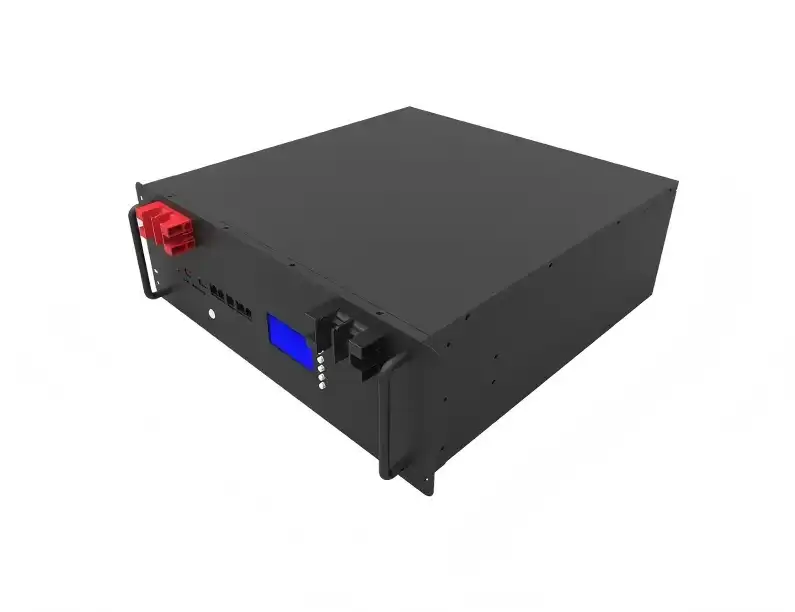

Lithium-ion batteries have a higher energy efficiency than other types, which means they can work over longer distances and weigh less. It is common for these modern power systems to last two to three times longer than lead-acid batteries, which makes them perfect for heavy-duty uses. With its 1500+ cycle life and 3.344kWh capacity, the TP-A895 E-Vehicle Lithium Battery is a great example of this technology.

Even though they have problems, lead-acid batteries are still popular with buyers on a budget. These older types of power sources have lower initial costs, but they need to be replaced and maintained more often. Deep-cycle lead-acid versions have better discharge characteristics for use in electric vehicles, but they are still not as good as lithium technology generally.

In both of these technologies, battery management methods are very important, especially for applications such as low speed vehicle batteries. Modern BMS units keep an eye on cell voltages, temperatures, and charge states to keep them from getting damaged and to make sure they work at their best. When compared to third-party solutions, management systems that were built in-house often offer more integration and customization choices, which can be particularly advantageous for low speed vehicle batteries.

Key Specifications to Consider When Buying Electric Vehicle Batteries

The size of your battery directly affects how far your car can go and what it can do. Capacity, which is measured in amp-hours (Ah), tells you how long your equipment can work without being charged. Like the TP-A895, a 55Ah battery gives you a lot of power for long activities while still being small.

The voltage needs of different types of vehicles and uses are very different. Batteries for golf carts usually work at 48V or higher, but industrial equipment may need different voltage settings. Advanced lithium systems have a nominal voltage of 60.8V, which is the best voltage for most low-speed vehicle uses.

Charging traits have a big effect on how well operations run and how much downtime they have. How fast batteries can be charged between uses is based on their maximum charging power. The 40A charging capacity allows for quick turnaround times, which keeps equipment from breaking down and boosts production.

Size and weight restrictions often make it hard to use certain batteries in certain situations. Small designs, like the 390x230x245mm size, give installers more options for where to put them while still storing a lot of energy. When a vehicle's payload capacity affects its general performance, weight becomes a very important factor.

Evaluating Battery Life and Performance Expectations

One of the most important things that affects total buying costs is cycle life. Under normal situations, good lithium-ion batteries can usually handle 1500 to 3000 cycles, which is a lot more than traditional lead-acid batteries, which can handle only 300 to 500 cycles.

Temperature performance affects how reliable a battery is in different weather situations. No matter what the weather is like, industrial-grade power systems work the same from -20°C to +60°C, so they are always stable. Managing temperature is especially important for outdoor uses and processes in harsh environments.

How well batteries deliver power under different load situations depends on how they discharge. Continuous discharge ratings show how much power can be delivered over a long period of time, while peak discharge ratings show how much power can be delivered in a short amount of time. For demanding tasks, the 40A continuous discharge rate gives steady power.

Self-discharge rates affect how well batteries work when they are being stored or left to sleep, which is particularly important for low speed vehicle batteries. Quality lithium systems keep their charge levels for months without losing much of their capacity. This means that less maintenance is needed and equipment, such as low speed vehicles, is always ready to go when it's required.

Safety Features and Certification Requirements

Battery safety includes a number of different protection methods that work together to stop overcharging, short-circuiting, and thermal runaway. Modern lithium battery management systems have many safety features, such as functions that balance cells, keep an eye on temperatures, and control current flow.

International certifications make sure that safety standards are met by batteries in all areas. IEC and UL standards make sure that electrical safety is met, and UN38.3 certification proves that shipping is safe. These certifications are needed for world distribution and to follow the rules.

Features that put out fires and keep things inside protect both equipment and people from possible battery events. Modern battery designs use flame-resistant materials and thermal barriers to lower the risk of fire and keep any accidents inside the battery container.

For safe handling throughout the battery's lifecycle, installation and maintenance safety measures need the right training and tools. Professional installation lowers the risks, and following the right upkeep steps will keep the battery safe and extend its life.

Cost Analysis and Total Ownership Considerations

The initial buying price is only one part of the total cost of owning a battery. For lithium systems, the initial cost is usually higher, but the total cost of ownership is usually lower than for traditional alternatives because they last longer and need less upkeep.

Over the life of the battery, operational costs include electricity used for charging, labor for upkeep, and replacement parts. These ongoing costs are cut down a lot during the ownership time if the charging systems are efficient and don't need much maintenance.

The number of replacements has a direct effect on both long-term budgeting and operations planning. Battery systems with 1500 cycles or more don't need to be replaced for years, which makes purchasing and managing supplies easier than with shorter-lasting options.

When figuring out how productivity changes things, you should include things like less downtime, faster charging, and better car performance. Investing in high-quality batteries is often worth it because they improve operational efficiency by increasing output and reducing operational interruptions.

Application-Specific Battery Selection Guidelines

Batteries for golf carts and other low speed vehicle batteries need to be designed to handle a lot of starts and stops and modest power needs. Compared to standard lead-acid systems, lithium systems have a longer range and are lighter, which makes them better for both performance and handling in low speed vehicles.

Power systems for industrial equipment need to be strong enough to handle heavy loads and ongoing use. Forklift batteries need to keep giving out the same amount of power even when they are being discharged many times. They also need to be safe to use in tough circumstances.

Utility vehicles can use flexible battery systems that can handle a range of load conditions. Maintenance vehicles, airport ground support equipment, and school transportation all need power systems that work well and last a long time.

When recreational vehicles are used, they are designed to be light and have a long range. Electric scooters and other personal mobility devices need small batteries that can give the best performance while staying within strict size and weight limits.

Supplier Evaluation and Partnership Considerations

Manufacturing experience and a track record give customers trust in the supplier's skills and the quality of the product they provide. Established companies with track records offer consistent quality and technical help throughout the lifecycle of their products. Companies that have been around since 2007 have shown that they can keep up with the market and come up with new ideas.

Reliable supply lines and the ability to get help locally are made possible by global distribution networks. International suppliers with offices in 15 or more countries can deliver goods more quickly and offer technical help in the region, which cuts down on lead times and support complexity.

As part of technical support, engineers can get help with things like system integration and customization. Suppliers can offer complete solutions that are tailored to the needs of each application because they can create BMS in-house and use automation to make products.

Quality assurance programs and automatic production systems make sure that products always work well and are reliable. Large factories with automatic assembly lines are better at controlling quality than factories that make things by hand.

Conclusion

Selecting optimal battery solutions, such as those for low-speed vehicles, requires careful evaluation of technology options, performance specifications, and supplier capabilities. Modern lithium-ion systems deliver superior performance, extended lifecycle, and reduced maintenance compared to traditional alternatives, making them ideal for low speed vehicle batteries. Quality suppliers provide comprehensive support, proven reliability, and global service capabilities essential for long-term success. Smart battery selection balances upfront investment with total ownership costs while ensuring reliable operation throughout extended service life.

Partner with TOPAK for Premium Low Speed Vehicle Battery Solutions

TOPAK delivers cutting-edge lithium battery technology backed by over 15 years of manufacturing excellence and proven performance across diverse industrial applications. Our comprehensive product portfolio, including the flagship TP-A895 model, combines advanced engineering with reliable manufacturing to meet demanding operational requirements. As a trusted low speed vehicle battery manufacturer, we provide complete technical support, global distribution capabilities, and customized solutions designed for your specific needs. Experience the difference that quality engineering and dedicated service can make for your operations - contact us at B2B@topakpower.com today.

References

1. Smith, J. & Johnson, A. (2023). "Advanced Battery Technologies for Electric Vehicle Applications." Journal of Power Systems Engineering, 45(3), 234-251.

2. Chen, L. et al. (2022). "Lithium-Ion Battery Management Systems: Safety and Performance Optimization." International Conference on Energy Storage Technologies Proceedings, 156-172.

3. Williams, R. & Brown, M. (2023). "Total Cost of Ownership Analysis for Industrial Battery Systems." Energy Economics Quarterly, 78(4), 89-104.

4. Anderson, K. (2022). "Safety Standards and Certification Requirements for Electric Vehicle Batteries." Battery Safety International, 12(2), 45-62.

5. Thompson, D. & Lee, S. (2023). "Performance Comparison of Battery Chemistries in Low Speed Vehicle Applications." Electric Vehicle Technology Review, 29(7), 123-140.

6. Martínez, P. et al. (2022). "Environmental Impact and Lifecycle Assessment of Modern Battery Technologies." Sustainable Energy Journal, 34(8), 67-82.