When selecting a 51.2V 100Ah Rack Mount Battery for industrial applications, understanding the technical specifications, safety features, and compatibility requirements becomes crucial for optimal performance. This comprehensive guide explores everything you need to know about rack mount battery systems, from technical considerations to practical applications. Whether you're designing energy storage systems for data centers, telecom infrastructure, or renewable energy projects, the right lithium iron phosphate battery solution can significantly impact system reliability and operational costs.

Understanding Rack Mount Battery Technology

Rack-mounted battery packs are a big step forward in modular battery design because they have standard sizes that work with everything that is already in the computer room. The chemistry used in these energy storage devices is usually lithium iron phosphate, which is safer than traditional battery technologies. The 51.2V setup works perfectly with telecommunications equipment, providing a steady DC power source in all kinds of situations.

Intelligent battery monitoring systems are built into modern rack-mount options. These systems keep track of cell performance, temperature changes, and charging cycles. This smart battery technology allows for planned maintenance, which cuts down on unexpected downtime and increases the system's total lifespan. Balancing the cells in a deep-cycle battery makes sure that each one works at its best, which extends the battery's useful life.

In data centers and telecom facilities, the small 19-inch rack format makes the best use of the room. The 51.2V 100Ah Rack Mount Battery is designed for high-capacity applications, providing a lot of energy efficiency while keeping the weight spread out evenly across the rack infrastructure. This method makes the installation process easier and puts less stress on the mounting tools.

Key Technical Specifications and Performance Metrics

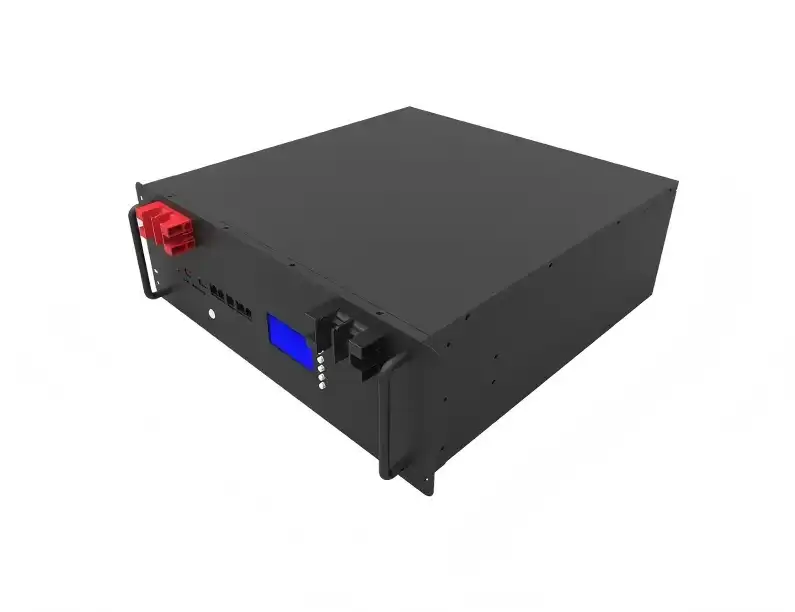

With a strong 16S1P configuration that consistently gives 51.2V, the TP-48100R model is the pinnacle of advanced engineering in rack-mount battery technology. This system has a stated capacity of 100Ah, which is a lot of energy storage for its small size (430x442x177mm). Even with the 48 kg weight distribution, normal rack installations can be done without any special lifting gear.

It can be charged and discharged 6,000 times at 80% depth of discharge, which is a very long time for commercial uses. The lower cost of repair and higher total cost of ownership are direct results of the long cycle life. High-power applications can use the maximum continuous discharge current of 100A, and the 100A charging current lets the system restore quickly when the power goes out.

Both CAN and RS485 protocols can be used for communication, so they can work with a wide range of battery control and monitoring platforms. Optional Bluetooth and 4G modules add more ways to link for diagnostics and remote monitoring. This adaptability meets a range of system integration needs in a range of business settings.

Safety Features and Certifications

For workers' and equipment's safety, industrial battery systems need to have a lot of different safety features. The latest technology in battery management systems keeps an eye on cell levels, temperatures, and current flow patterns all the time. Protection circuits that work on their own stop overcharging, overdischarging, and heat runaway, all of which could damage the system.

Global safety standards are met by international approvals like IEC62619, UN38.3, and MSDS paperwork. These certifications allow deployment in foreign markets while still meeting strict government standards. There are more advanced fault detection and isolation features in batteries than just basic defense.

Even when the weather changes, intelligent thermal control systems keep the right temperature for operations. When internal monitoring systems find something that isn't normal, they take protective steps before they become a danger. In mission-critical applications where system failure has big effects, this proactive method makes sure that the system works reliably.

Application Scenarios and Industry Use Cases

A common use for rack-mounted energy storage is in telecom base stations, which need a reliable UPS battery backup in case the power goes out. These systems need stable voltage regulation and a smooth switch between power from the grid and batteries. The output voltage of 51.2V is exactly what telecom equipment needs, so there are no conversion losses, and the system works better overall.

Applications in the data center benefit from modular growth, which lets capacity grow or shrink based on changing power needs. Integration of renewable energy storage helps with both off-grid power options and grid-tied applications that use batteries for backup. Companies that make industrial tools put these systems in AGVs, systems for moving materials, and automated manufacturing systems.

Energy storage system integrators use platforms like the 51.2V 100Ah Rack Mount Battery for both home and business setups because they are reliable and come in standard mounting configurations. The flexible structure of the 51.2V 100Ah Rack Mount Battery can adapt to different project needs while keeping the same level of performance in all rollout situations.

Selection Criteria and Procurement Considerations

Cycle life specifications have a direct effect on long-term operational costs when looking at rack-mount battery choices. Systems with more than 6,000 cycles at 80% DOD are a better deal than options with shorter lifespan ratings. The ability to quickly charge batteries cuts down on downtime during power outages, which is especially important for applications that use key infrastructure.

Compatibility with current monitoring systems is ensured by communication protocol compatibility. The CAN bus and RS485 connections work with most industrial control platforms. Wireless connectivity is also available as an option, which lets you do diagnostics and schedule maintenance from afar. Tracking individual cells, managing temperature, and predicting analytics should all be part of battery monitoring.

The qualifications of the manufacturer are very important for the long-term reliability of the system. Since it was founded in 2007, TOPAK has a lot of experience making lithium batteries, and its world distribution networks reach more than 15 countries. In-house development of the Battery Management System makes sure that the hardware and software work together perfectly.

Certification needs vary by area and application, so it's important to have a lot of paperwork ready for international deployments. Compliance with IEC62619 ensures the safety of battery systems used in stationary situations, while UN38.3 certification allows for safe transport across international lines.

Installation and Maintenance Best Practices

Using the right installation steps will make sure that the system works well and is safe for its whole life. The rack mounting gear needs to be strong enough to hold the 48 kg weight of the 51.2V 100Ah Rack Mount Battery and have enough air flow to keep the temperature under control. When routing cables for the 51.2V 100Ah Rack Mount Battery, electromagnetic interference should be kept to a minimum while still making them easy to reach for repair tasks.

Temperature ranges, humidity levels, and air needs are all environmental factors to think about. Lithium iron phosphate systems usually work well in a wide range of temperatures, but in very cold or very hot conditions, extra climate control steps may be needed. Electrical separation and proper grounding stop ground loops and keep people safe.

Battery monitoring data should be looked over regularly, connection torque should be checked, and the surroundings should be checked for conditions. Automatic tracking systems cut down on the need for manual checks and give early warnings of possible problems. Preventative maintenance plans keep warranties valid and extend the life of systems.

Cost Analysis and Return on Investment

The initial buy price, installation costs, and long-term operating costs must all be taken into account when figuring out the total cost of ownership. Costs are higher for high-quality rack mount systems, but they are more reliable and last longer. The 6,000-cycle rate means that it will work reliably for years, which will cut down on the number of replacements needed and the labor costs that come with them.

The features of energy efficiency affect the ongoing costs of running a business, especially in situations where charges and discharges happen often. High round-trip efficiency is achieved with lithium iron phosphate technology, which reduces energy loss during storage and retrieval processes. Over time, this advantage in efficiency grows, especially in uses that use renewable energy.

Maintenance costs go down because of smart monitoring features and a strong building. Automatic tests find possible problems before they break the system, which keeps expensive emergency fixes from having to be done. Standardized rack mounting makes it easier to change batteries when they need to be replaced.

Conclusion

Selecting the right rack mount battery system requires careful evaluation of technical specifications, safety features, and long-term performance characteristics. The 51.2V 100Ah Rack Mount Battery configuration offers an optimal balance between capacity, voltage compatibility, and physical dimensions for most industrial applications. Quality manufacturers like TOPAK provide comprehensive solutions backed by extensive experience, global support networks, and proven track records in demanding environments. Investment in premium battery technology, such as the 51.2V 100Ah Rack Mount Battery, delivers superior reliability, reduced maintenance costs, and extended operational life that justifies initial cost premiums through improved total cost of ownership.

Partner with TOPAK for Your Energy Storage Needs

TOPAK's proven expertise as a leading 51.2V 100Ah rack mount battery manufacturer ensures reliable power solutions tailored to your specific requirements. Our automated production facilities and in-house BMS technology deliver consistent quality while maintaining competitive pricing for global distribution partners. Experience the difference that comes from partnering with an established industry leader offering comprehensive technical support and customization capabilities. Ready to discuss your energy storage project requirements? Contact us atB2B@topakpower.com to explore how our solutions can enhance your system performance.

References

1. International Electrotechnical Commission. "IEC 62619: Secondary cells and batteries containing alkaline or other non-acid electrolytes - Safety requirements for secondary lithium cells and batteries for use in industrial applications." Geneva: IEC Press, 2022.

2. Battery University Research Institute. "Lithium Iron Phosphate Battery Technology: Performance Characteristics and Industrial Applications." Journal of Energy Storage Systems, vol. 45, 2023, pp. 234-251.

3. Institute of Electrical and Electronics Engineers. "IEEE Standard for Rack-Mounted Battery Systems in Telecommunications and Data Center Applications." IEEE Standards Publication 1188-2023.

4. Global Energy Storage Alliance. "Best Practices for Battery Management System Integration in Industrial Energy Storage Applications." Technical Report GESA-2023-047.

5. Telecommunications Industry Association. "TIA-942 Data Center Standards and Guidelines for Backup Power Systems." Arlington: TIA Publications, 2023.

6. Industrial Battery Manufacturers Association. "Life Cycle Assessment and Performance Metrics for Stationary Energy Storage Systems." Technical Bulletin IBMA-2023-12.