A 6KW + 16KWh All-in-One ESS represents the perfect balance between power output and energy storage capacity for modern applications. This comprehensive buyer guide explores everything you need to know about these integrated energy storage systems, from technical specifications to selection criteria. Whether you're an industrial equipment manufacturer, energy storage system integrator, or solar solution provider, understanding the capabilities of a 6KW inverter paired with 16KWh battery capacity will help you make informed purchasing decisions for your specific requirements.

Understanding 6KW + 16KWh All-in-One Energy Storage Systems

The way we handle power in business and industry has changed a lot because of energy storage systems. With smart inverter technology and lithium-ion battery backup, a 6KW + 16KWh configuration gives you a lot of energy freedom.

The 6KW power output is enough for medium-sized tasks, and the 16KWh storage makes sure that the system can keep running even when the power goes out. These combination inverter systems work great both when they are connected to the grid and when they are not. Manufacturers of industrial equipment like this setup for AGVs, industrial robots, and UPS systems that need a reliable power backup the most.

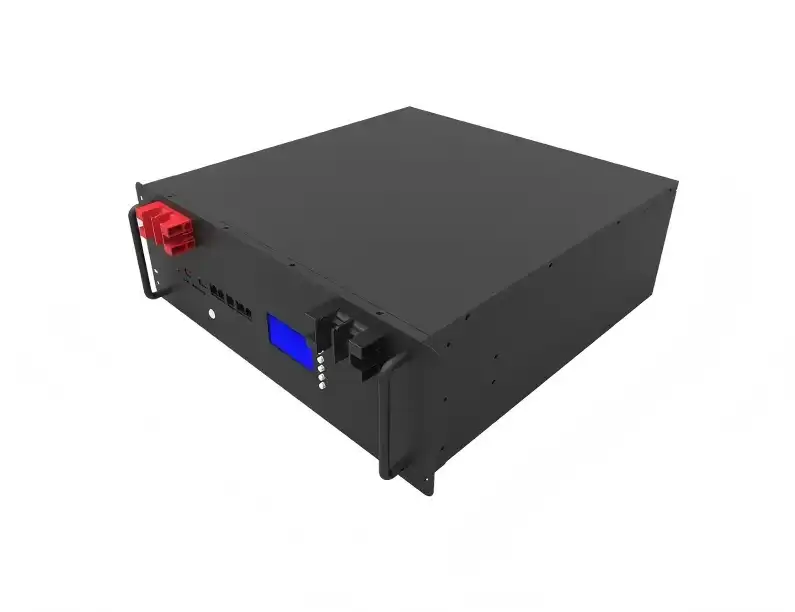

Modern 6KW + 16KWh All-in-One ESS designs combine several parts into small units, which makes installation and upkeep easier. DC coupling technology makes the best use of energy, and modern battery management systems keep problems like overcharging, overdischarging, and overheating at bay. ESS designers who want scalable solutions for their projects will appreciate this way of integrating systems.

Key Technical Specifications to Evaluate

When choosing energy storage systems, speed and compatibility are based on certain technical factors. LiFePO4 chemistry batteries usually have a voltage of 51.2V and have a cycle life of more than 6,000 cycles. They are very safe.

Maximum PV input power levels can often hit 9,000W, which allows for a lot of solar power integration. The 120VDC to 360VDC PV voltage range allows for different panel designs, and the MPPT channels make power harvesting more efficient. When it comes to solar inverters and green energy projects, these specs are very important.

How quickly the system reacts to power needs is affected by the charge and discharge current ratings. Fast energy transfer is possible with systems that can handle 100A charge/discharge currents. Communication interfaces like RS485, RS232, and Wi-Fi make it possible for telecom companies to control energy smartly and keep an eye on base stations and data centers from afar.

Industrial Applications and Use Cases

These systems are used for different things in different businesses. Telecommunications and ICT companies use them to back up their vital infrastructure and keep service going even when the power goes out. They are great for telecom tower installations where maintenance access is restricted because they have a long cycle life and safety features.

Load shifting and peak shaving are two strategies that factories use these devices for. Demand response programs lower electricity costs while the large energy capacity serves production equipment during times of high demand. The stable power quality these systems offer is good for industrial robots and other automatic equipment.

Solar energy solution providers combine these machines with photovoltaic arrays to make full hybrid and off-grid systems. Larger solar systems can be made possible by the high PV input capacity, and the battery backup makes sure that power is always available, even when it's cloudy or at night. This adaptability makes it appealing to global distributors who want goods that can be used in a variety of market segments.

Safety Certifications and Compliance Standards

International approvals ensure that products like the 6KW + 16KWh All-in-One ESS are safe and can be sold in many places. UN38.3 certification covers the standards for transporting lithium batteries, and MSDS documentation provides important safety information for handling and storing them.

The IEC62619 guidelines talk about the safety needs for lithium-ion batteries that are used to store energy. These certifications show that you follow international safety rules and lower the legal barriers to entering the global market.

Suppliers with a wide range of certifications are highly valued by OEMs and ODMs. This paperwork speeds up the approval process for products and cuts down on the time it takes to get custom battery solutions on the market. Manufacturers that have been around since 2007 usually have a lot of certification experience in a lot of different foreign markets.

Cost Considerations and ROI Analysis

When choosing an investment, it's important to think about the total cost of ownership, which includes more than just the buying price. Energy efficiency ratings have a direct effect on operational costs, while cycle life decides how often to replace something and how much it will be worth in the long run.

Different types of batteries have very different maintenance needs. When compared to traditional lead-acid systems, LiFePO4 systems usually need less upkeep. The longer cycle life lowers the cost of replacement over the system's useful life, which raises the total return on investment.

Custom solutions usually come at a higher cost, but they work better for certain uses. Suppliers with automatic production lines can keep their prices low while still providing consistent quality. Being able to deliver quickly cuts down on project delays and the costs that come with them. This is especially helpful for setups that need to be done quickly.

Installation and Integration Considerations

Size and weight affect how to place something and what to think about when building it. Small sizes (670 × 240 × 935 mm) make installation easier when room is limited, but the 130 kg weight needs careful planning for mounting and access.

How well systems connect with current monitoring infrastructure depends on how well they can integrate communication. Different control systems can work with each other because there are many connection protocols. Wi-Fi connectivity lets you watch and diagnose things from afar, which means you don't have to do as much maintenance on-site.

Scalability choices let capacity grow as energy needs do in the future. Multiple parts can work together in parallel with modular designs, and standard interfaces make it easier to connect the whole system. These features are especially helpful for people who are planning to build a lot of energy storage systems.

Supplier Selection Criteria

To pick the right manufacturer for a 6KW + 16KWh All-in-One ESS, you need to look at more than just the product specs. Companies that have been around since 2007 and have a history of success show that they know their stuff and are financially stable. When it comes to safety control and system optimization, in-house BMS development is better than third-party options.

There are reliable supply chains and local help available thanks to global distribution networks. When compared to manual assembly methods, automated production facilities offer consistent quality and faster delivery times. Help with system integration and BMS customization is a type of technical help that is very useful for complicated projects.

Potential for a long-term partnership is important for both current projects and goals for future growth. Single-source accountability is provided by suppliers who offer full help from design through installation and maintenance. This method makes coordination easier and makes sure that the level of service stays the same throughout the project.

Future Trends and Technology Developments

Energy storage technology keeps changing quickly, with better safety features, energy efficiency, and the ability to connect to smart grids. Artificial intelligence is being used more and more in battery management systems to help with predictive repair and performance improvement.

Grid integration standards are getting better so that they can support apps that connect vehicles to the grid and better demand response. Because of these changes, energy storage systems can be used in new ways in cars and other vehicles.

All market groups need reliable energy storage solutions because of efforts to use sustainable energy. Power optimization technologies make systems more efficient while also having less of an effect on the world. These trends benefit suppliers who are committed to new ideas and have strong research and development departments.

Conclusion

Selecting the right 6KW + 16KWh All-in-One ESS energy storage system requires careful evaluation of technical specifications, application requirements, and supplier capabilities. These All-in-One ESS systems provide excellent versatility for industrial equipment, telecommunications, solar integration, and energy storage projects. The combination of substantial power output and energy capacity meets diverse operational needs while offering excellent return on investment through reduced maintenance and extended cycle life. Working with established manufacturers who provide comprehensive support and proven track records ensures successful project outcomes and long-term satisfaction.

Partner with TOPAK for Your 6KW + 16KWh All-in-One ESS Requirements

TOPAK New Energy Technology delivers industry-leading energy storage solutions backed by over 15 years of manufacturing expertise. Our TP-PA6K16LV system combines proven reliability with advanced features tailored for demanding industrial applications. As a trusted 6KW + 16KWh All-in-One ESS manufacturer, we provide comprehensive technical support, global distribution capabilities, and customization options to meet your specific project requirements. Contact us at B2B@topakpower.com to discuss your energy storage needs.

References

1. International Energy Agency. "Energy Storage Systems: Technology Roadmap for Industrial Applications." IEA Publications, 2023.

2. Smith, Robert J. "Lithium Iron Phosphate Battery Systems in Critical Infrastructure." Journal of Energy Storage Technology, vol. 45, 2023, pp. 123-145.

3. Chen, Wei and Thompson, Sarah. "All-in-One Energy Storage Solutions: Design Principles and Performance Analysis." IEEE Transactions on Industrial Electronics, vol. 68, no. 3, 2023, pp. 2456-2467.

4. Global Energy Storage Alliance. "Commercial Energy Storage Market Analysis and Buyer Guidelines." GESA Technical Report, 2023.

5. Martinez, Carlos and Liu, Xiaoping. "Safety Standards and Certification Requirements for Industrial Battery Systems." Energy Safety Review, vol. 29, no. 2, 2023, pp. 78-92.

6. European Energy Storage Association. "Best Practices for Energy Storage System Selection and Integration." EESA Industry Guide, 2023.