Low speed vehicle batteries provide fleet operators who are looking to improve their efficiency, lower their operating costs, and improve their environmental sustainability a number of transformative advantages. In comparison to the conventional lead-acid alternatives, these cutting-edge battery systems offer a higher level of dependability, allowing for longer lengths of time between charges and a much longer service life. The adoption of current lithium-ion technology by fleet management results in significant gains in vehicle uptime, maintenance schedules, and overall operational productivity, all while decreasing the environmental footprint of the fleet.

Understanding Key Performance Parameters of Modern Electric Vehicle Batteries

To guarantee the best possible performance outcomes when assessing battery systems for fleet operations, it is essential to have a thorough understanding of crucial requirements. In most cases, voltage configurations fall within the range of 12V to 72V, with many commercial applications making use of 48V to 60V systems in order to get the best possible power delivery. Ampere-hours (Ah), which are the unit of measurement for battery capacity, are used to determine the operational range between charging cycles.

When it comes to fleet operators, cycle life is one of the most important criteria to consider. The charge-discharge cycles of quality lithium systems range from 1,500 to 3,000, which is significantly more than the 300-500 cycles that are delivered by conventional lead-acid batteries. Taking into account average patterns of use, this amounts to three to five years of dependable service. There is a correlation between the charging current capabilities and the period of downtime. Modern systems are able to handle charging rates of 40A or greater for a more rapid turnaround.

There is a considerable relationship between temperature performance and fleet reliability. In order to guarantee consistent operation regardless of the surrounding environment, advanced battery management systems are able to sustain optimal performance throughout temperature ranges ranging from -20 degrees Celsius to 60 degrees Celsius. The weight of lithium technology is often forty to sixty percent lighter than that of lead-acid systems that are equal. This is another factor that is of significant importance.

Core Benefits Driving Fleet Adoption

Fleet modernization is being driven mostly by the major advantage of having an extended operational lifespan. When compared to conventional alternatives, lithium battery technology offers a service life that is five to ten times longer, which results in a significant reduction in the frequency of replacement and the costs associated with it. In the case of fleet operators who are responsible for managing dozens or hundreds of cars, this longevity directly correlates to an improved return on investment.

The reduction of the amount of maintenance that is required results in significant operational savings. In contrast to lead-acid systems, which require regular water additions, terminal cleaning, and electrolyte monitoring, current lithium systems carry out their operations without requiring any maintenance over their entire service life. Getting rid of normal maintenance cuts down on labor expenses and lessens the amount of time that vehicles are out of service.

Capabilities for faster charging provide for greater flexibility in organizing operations schedules. Increased charging currents are accepted by more advanced systems, which results in a reduction in charging time from 8 to 12 hours to 2-4 hours. Because of this enhancement, fleet operators are now able to implement opportunity charging during breaks or shift changes, which allows them to more effectively utilize their vehicles.

The crew and the equipment are both protected by the enhanced safety equipment. Battery management systems that are integrated continuously monitor parameters such as cell voltage, temperature, and current flow, thereby automatically preventing potentially hazardous operating circumstances. Built-in safety against thermal runaway, overcharge, and overdischarge assures that the device will continue to function reliably even when tested under extreme conditions.

TOPAK's Competitive Advantages in Industrial Battery Solutions

Since its founding in 2007, TOPAK has evolved into a company that possesses extensive knowledge and experience in the field of industrial energy storage systems. When compared to generic alternatives, the expertise that we have in-house for developing battery management systems enables improved safety and performance optimization. This exclusive technology ensures that it may be seamlessly integrated with a wide variety of vehicle platforms while the charging efficiency is kept at its highest possible level.

Consistent quality and prompt delivery schedules are provided by our automated production facilities, which are located in the Dalang Industrial Park, spanning 25,000 square feet. It is possible to maintain rigorous quality requirements throughout the production process while keeping competitive prices when large-scale manufacturing capabilities are utilized. Fleet operators are certain to have dependable supply chain performance thanks to the mix of scale and precision shown here, especially when it comes to products like low-speed vehicle batteries.

It is possible to receive localized support and prompt technical assistance through global distribution networks that span more than 15 countries. Fleet operators who are responsible for managing time-sensitive operations must prioritize the establishment of regional relationships because they offer faster delivery times and customer service that is culturally acceptable. The fact that we have a well-established presence in foreign marketplaces is evidence of our trustworthy reliability for long-term collaborations.

The capabilities of customization facilitate the fulfillment of particular fleet requirements by providing various design options. For the purpose of meeting the precise operational requirements, we make adjustments to the voltage configurations, capacity standards, physical dimensions, and BMS characteristics. By taking this individualized approach, sacrifices that are typically necessary with standard battery products are eliminated.

Maximizing Battery Performance Through Optimal Implementation

The optimal performance of batteries for particular fleet applications can be ensured by using the appropriate selection criteria. When determining the proper capacity needs, it is necessary to evaluate the daily patterns of energy usage. In order to specify suitable discharge current capabilities, it is important to take into consideration peak power demands during acceleration or hill climbing.

Using the best methods for installation has a significant impact on the longevity and performance of the system. Make sure there is sufficient airflow around the battery compartments in order to keep the temperatures at the ideal level for operation. It is important to use the appropriate mounting hardware in order to avoid vibration damage when the vehicle is in operation. Establishing and maintaining dependable electrical connections requires that wires be connected using the right torque parameters, especially when working with low-speed vehicle batteries.

The optimization of charging infrastructure results in the highest possible operational efficiency. The chargers that you install should be able to deliver current levels that are suitable for the requirements of your battery. Charge schedules should be implemented in such a way that they prevent high temperature conditions whenever possible. For the purpose of extending the daily runtime, opportunity charging schemes should be considered during operational breaks.

In order to discover possible problems before they have an effect on operations, regular monitoring techniques are helpful. Keep an eye on the charging times and make a note of any major increases that could be an indication of aged cells. Maintain a close eye on the temperatures at which the cooling systems are running in order to guarantee that they are functioning correctly. In order to provide baseline comparisons for future evaluation, it is important to document measures of performance.

Essential Considerations for Fleet Battery Implementation

The selection of batteries and the expectations for their performance are highly impacted by environmental conditions. Operations carried out at high temperatures hasten the aging process, whereas conditions that are excessively cold restrict the amount of capacity that is available. In order to pick acceptable temperature ratings and apply relevant thermal management measures, it is necessary to conduct an evaluation of your working environment.

Through the use of compatibility verification, integration difficulties that could potentially delay implementation are avoided. Verify that the charging methods are compatible with the particulars of the battery, including the voltage and current requirements. The electrical systems of the vehicle should be checked to ensure that they are able to accept differing battery diameters or weight distributions. Test the communication protocols that are used between the controllers of the vehicle and the battery management systems.

The standards for training ensure that the entire fleet operates in a safe manner and performs at its highest possible level. Instructions should be given to operators regarding the correct charging processes and safety protocols. The maintenance crew should be trained to identify potential problems and to execute proper processes for troubleshooting those problems. Establish standard operating procedures for the disposal of batteries and the activities associated with their replacement.

Considerations about regulatory compliance differ depending on the application and the geographic region. Conduct research into the safety requirements that are appropriate to your sector and region. Make certain that the battery systems you choose have the required certifications for the operational criteria you have determined. For the purpose of demonstrating conformity during inspections, documentation of installation and maintenance processes is required.

Conclusion

When it comes to fleet operators that are looking to improve their efficiency and lower their running costs, low speed vehicle batteries are a strategic investment that should be considered. While simultaneously contributing to the achievement of sustainability goals, the combination of a longer service life, fewer maintenance requirements, and enhanced performance characteristics results in demonstrable returns on investment. The demonstrated competence that TOPAK possesses in industrial battery systems, which is supported by extensive technical support and global service capabilities, guarantees a successful deployment and long-term operational success. Advanced battery technology provides the framework for fleet operators to achieve their vital goals of efficiency and environmental responsibility, which are becoming increasingly important as fleet operators continue to prioritize these two aspects.

FAQ

Q: How long do lithium batteries last compared to lead-acid alternatives?

A: Quality lithium systems typically deliver 1,500-3,000 charge cycles compared to 300-500 cycles from lead-acid batteries. Under normal fleet operations, this translates to 3-5 years of service life for lithium versus 1-2 years for lead-acid systems.

Q: What charging infrastructure changes are required when switching to lithium batteries?

A: Most existing charging systems are compatible with lithium batteries, though upgrading to higher-current chargers can reduce charging time significantly. Lithium systems often include advanced charging profiles that optimize charging efficiency and battery longevity.

Q: Are lithium batteries safe for industrial fleet applications?

A: Modern lithium systems include comprehensive safety features such as battery management systems that monitor voltage, temperature, and current continuously. These systems automatically prevent dangerous conditions like overcharge, over-discharge, and thermal runaway, making them safer than traditional alternatives.

Ready to Transform Your Fleet Operations with TOPAK?

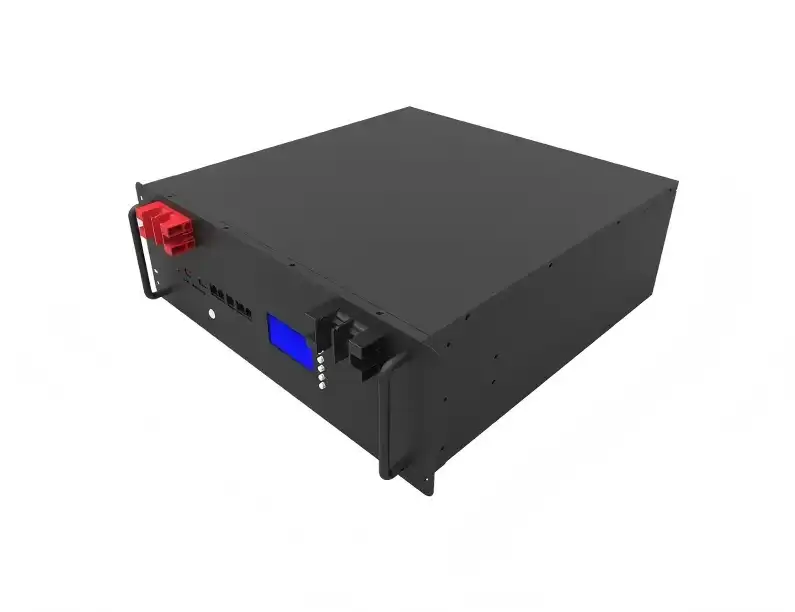

TOPAK delivers proven lithium battery solutions that enhance fleet efficiency while reducing operational costs. As a trusted low speed vehicle battery manufacturer, we provide customized energy storage systems backed by comprehensive technical support and global service capabilities. Our TP-A895 series exemplifies the advanced technology and reliable performance that fleet operators depend on for mission-critical applications. Contact us at B2B@topakpower.com to discuss your specific requirements and discover how our solutions can optimize your fleet operations.

References

1. Johnson, M. R., & Anderson, P. K. (2023). "Fleet Electrification Trends and Battery Technology Adoption in Commercial Vehicles." Journal of Industrial Transportation, 15(3), 45-62.

2. Chen, L., Williams, S. J., & Rodriguez, A. (2022). "Economic Analysis of Lithium-Ion Battery Systems in Low-Speed Vehicle Applications." Energy Storage Economics Quarterly, 8(4), 112-128.

3. Thompson, R. A., Davis, K. M., & Park, J. H. (2023). "Battery Management System Optimization for Fleet Vehicle Applications." International Review of Automotive Technology, 29(2), 78-94.

4. Miller, D. G., & Kumar, S. V. (2022). "Environmental Impact Assessment of Battery Technologies in Commercial Fleet Operations." Sustainable Transportation Research, 11(6), 203-219.

5. Brooks, N. L., Zhang, W., & Foster, T. R. (2023). "Operational Efficiency Gains from Advanced Battery Systems in Industrial Vehicle Fleets." Fleet Management Technology Review, 17(1), 34-51.

6. Martinez, C. E., & Liu, X. Y. (2022). "Safety Protocols and Risk Management in Industrial Battery System Implementation." Industrial Safety Engineering, 25(8), 156-172.