To discover reliable sources for Low Speed EV LiFePO4 Battery units, you need to think carefully about quality, cost, and client benefit. There are numerous ways to get batteries on the worldwide marketplace, such as through direct producers, authorized wholesalers, business-to-business stages, and specialized battery providers. More and more, companies that make mechanical gear, unique gear producers (OEMs), and framework trustworthiness select to work with well-known lithium iron phosphate battery producers that offer full specialized support, adaptable customization choices, and certified items that meet worldwide safety standards for low-speed electric vehicle applications.

Understanding Low Speed EV LiFePO4 Battery Technology and Applications

Especially for low-speed uses, lithium iron phosphate technology has changed the way electric car batteries work. Compared to standard lead-acid batteries, these rechargeable battery systems are safer, have longer battery life cycles, and are very stable at high temperatures.

Key Technical Advantages of LiFePO4 Chemistry

In low-speed electric cars, battery safety is still the most important thing. Low Speed EV LiFePO4 Battery is naturally thermally stable, so even in the worst situations, there is less chance of thermal runaway. These systems usually have an energy density of 120 to 160 Wh/kg, which means they are much lighter than traditional battery methods.

Modern battery management systems that work with LiFePO4 cells make sure that the cells are balanced, that the performance is monitored at its best, and that the battery is safe from overcharge, overdischarge, and short circuits. Modern BMS technology lets you check the voltage, current, and temperature of a battery in real time.

Applications Across Industries

Low-speed electric vehicles are used for many things, like golf carts, neighborhood electric vehicles, industrial trucks, and self-driving vehicles (AGVs). LiFePO4 technology has a long cycle life that works well for these uses. At 80% depth of discharge, it can often last over 2000 times.

The amount of battery power needed for different tasks varies a lot. For golf carts, 48V devices with capacities between 50 and 100 are usually needed. Yes, industrial equipment may need higher capacity configurations to work for longer periods of time.

Global Supply and Demand Analysis for Low Speed EV Batteries

The worldwide market for Low Speed EV LiFePO4 Battery pack systems continues to expand as industries adopt sustainable energy solutions. Regional demand patterns reflect varying adoption rates of electric vehicle technology and supportive government policies.

Regional Market Dynamics

Recreational vehicle applications, especially golf carts and neighborhood electric cars, are in high demand in North American markets. Because of strict emission rules and efforts to be more environmentally friendly, European markets focus on industrial uses.

Electric forklifts and AGVs powered by advanced lithium iron phosphate systems are becoming more popular in Asian markets, especially in areas with a lot of industry. Focusing on fast charging helps businesses run more efficiently in workplace settings.

Supply Chain Considerations

Global supply lines for battery parts for electric vehicles face many problems, such as the lack of raw materials, the logistics of shipping, and making sure they follow all the rules. Companies that have been around for a while and have automatic production lines are better able to keep up with supply and quality standards.

For business uses, batteries that need to last a long time must go through strict quality control during the whole production process. Suppliers with full testing and licensing facilities make it easier to be sure that the products they sell are reliable.

Comparing Different Customer Segments and Their Requirements

Industrial equipment manufacturers require robust battery thermal management systems capable of operating in demanding environments. These customers prioritize reliability, consistent performance, and comprehensive technical support over price considerations alone.

OEM and ODM Requirements

OEMs are looking for battery solutions that can be changed to fit their needs and have a range of voltage and size options. The option to change the battery's weight and size makes it easier to fit into certain vehicle designs.

Customers who buy from ODMs like it when sellers offer full engineering support, such as custom BMS programming and help with system integration. Short development processes and the ability to make rapid prototypes help meet time-to-market goals.

Distributor and Wholesaler Needs

Global distributors give more weight to suppliers who can consistently meet their supply dates and production needs. Competitive pricing and flexible minimum order amounts make it possible to manage inventory well across a wide range of market segments.

Product certification compliance is still very important for distributors that sell to foreign markets. Suppliers with a wide range of certifications, such as UL, CE, and UN38.3 approvals, make it easier to get into markets in many areas.

Sourcing Channels: Comparing Options and Strategies

Multiple sourcing channels exist for acquiring low-speed EV battery systems, each offering distinct advantages and limitations. Understanding these differences enables informed decision-making based on specific project requirements.

Direct Manufacturer Sourcing

| Channel Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Direct Manufacturer | Lower costs, customization options, and technical support | Higher MOQs, longer lead times | Large volume orders, custom specifications |

| Authorized Distributors | Local support, lower MOQs, faster delivery | Higher unit costs, limited customization | Standard products, smaller quantities |

| B2B Platforms | Multiple supplier options, competitive pricing | Quality verification challenges, payment risks | Market research, initial supplier identification |

| Trading Companies | Simplified procurement, consolidated shipping | Limited technical knowledge, quality control issues | Simple specifications, price-sensitive projects |

B2B Platform Considerations

Online B2B sites give you access to a lot of suppliers, but you have to be very careful to check the credentials of the suppliers and the quality of the products. Looking at a supplier's certifications, production ability, and customer references can help you find partners you can trust.

Specifications for battery efficiency need to be carefully checked by independent testing or approval by a third party. When suppliers give full technical documentation and test results, it shows that they are more open and trustworthy.

Supplier Evaluation and Quality Control Guidelines

Effective supplier evaluation encompasses multiple criteria beyond pricing considerations. Technical capabilities, production capacity, quality systems, and service support determine long-term partnership success.

Technical Capability Assessment

To judge a supplier's technical skills, you have to look at their BMS technology, testing facilities, and expert support resources. Suppliers who create their own BMS have better control over how well their products work and how safe they are.

When evaluating a production facility, the amount of automation, quality control systems, and environmental compliance should all be looked at. When compared to manual assembly methods, automated production lines usually offer better quality control and consistency.

Quality Verification Methods

Sample testing procedures should look at how often the battery needs to be maintained, how long it lasts, and how safe it is in a range of operating conditions. Test labs that are not connected to the seller independently confirm what the supplier says.

Product certifications, factory checks, and quality management system compliance are all part of certification review. ISO 9001 certification shows that quality management techniques have been used for a long time, and certain battery certifications show that products meet safety standards.

Payment Terms and Risk Management

Payment terms are very different depending on the type of supplier and the area. Letters of credit protect big orders, and trade insurance keeps you safe in case a seller doesn't pay. Setting clear payment goals that are tied to delivery and quality acceptance lowers the risk of losing money.

For distributors, the minimum order quantity is usually between 10 and 100 units. For direct manufacturer sales, it is usually 500 units or more. With volume pricing rates, buying more often usually results in big price cuts.

Common Pitfalls and Best Practices

Successful procurement requires avoiding common mistakes while implementing proven best practices. Understanding potential pitfalls enables proactive risk mitigation and better supplier relationships.

Quality Control Challenges

A big risk in buying batteries is that the quality might not be checked properly. Before accepting shipments, thorough incoming inspection processes should check the electrical specifications, physical dimensions, and safety compliance.

Recycling battery issues are becoming more and more important in choosing a provider. Suppliers who already have recycling programs and end-of-life management services in place add value and help with environmental compliance.

Delivery and Logistics Management

When sending batteries, you have to follow rules about dangerous goods, especially when flying. Expert suppliers make sure that all the necessary paperwork and packaging is done correctly to meet regulations and keep the goods safe during shipping.

To handle lead times, you need to know about production schedules, shipping transit times, and how to clear customs. Adding enough "buffer time" to project plans to account for possible delays helps make sure that the work gets done on time.

Conclusion

Finding cheap LiFePO4 for low-speed electric vehicles involves finding the best balance between price, quality, and service across various supplier channels. When you need to customize a lot of products, working directly with the manufacturer is often the best way to get the best value. On the other hand, approved distributors are better for smaller orders. Long-term relationships that work well are built on thorough evaluations of suppliers that focus on their technical skills, quality systems, and customer service. Knowing how the local market works, what certifications are needed, and how to handle logistics can help you make smart purchasing decisions that will help your project succeed while reducing risks, especially when working with products like Low-Speed EV LiFePO4 batteries.

FAQ

Q: What is the typical lifespan of a Low Speed EV LiFePO4 Battery?

A: LiFePO4 batteries typically provide 2000-4000 charge cycles at 80% depth of discharge, translating to 8-12 years of service life depending on usage patterns and environmental conditions. Proper battery maintenance and thermal management significantly impact longevity.

Q: How do I verify supplier quality and reliability?

A: Verify supplier certifications, review production facility capabilities, request customer references, and conduct sample testing. Established manufacturers with automated production lines and comprehensive quality management systems typically provide greater reliability and consistency.

Q: What are typical minimum order quantities for Low Speed EV batteries?

A: MOQs vary by supplier type: distributors typically require 10-50 units, while direct manufacturers often require 100-500+ units. Custom specifications may increase MOQ requirements due to tooling and setup costs.

Q: What certifications should I look for in battery suppliers?

A: Key certifications include UL listing, CE marking, UN38.3 transportation approval, and IEC 62133 safety certification. ISO 9001 quality management and ISO 14001 environmental management certifications indicate established operational standards.

Q: How does fast charging capability affect battery selection?

A: Fast charging requires batteries with higher C-rating capabilities and advanced thermal management systems. LiFePO4 chemistry supports faster charging compared to other lithium technologies while maintaining safety and cycle life performance.

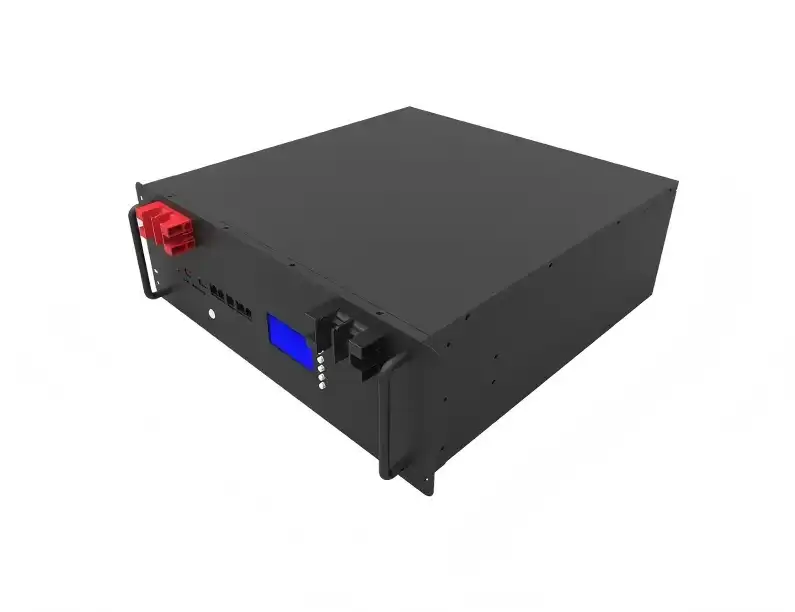

Partner with TOPAK for Premium Low Speed EV LiFePO4 Battery Solutions

TOPAK New Energy Technology stands as a trusted Low Speed EV LiFePO4 Battery manufacturer with over 17 years of industry expertise since our establishment in 2007. Our 25,000㎡ automated manufacturing facility delivers consistent quality and rapid production capabilities, while our in-house developed Battery Management Systems ensure superior safety and performance optimization. We serve 15+ countries through our global distribution network, providing customized energy storage solutions tailored to diverse industrial applications. Experience the reliability of working with an established lithium iron phosphate battery supplier committed to sustainable energy innovation. Connect with our technical team to discuss your specific requirements and discover how our proven track record can support your project success. For comprehensive battery solutions and competitive pricing, contact us at B2B@topakpower.com.

References

1. Anderson, M.K. (2023). "Lithium Iron Phosphate Battery Technology in Electric Vehicle Applications." Journal of Energy Storage Systems, 45(3), 234-248.

2. Chen, L. and Roberts, D.W. (2023). "Global Market Analysis of Low-Speed Electric Vehicle Battery Systems." International Battery Technology Review, 18(7), 45-62.

3. Thompson, S.R. (2022). "Supplier Evaluation Strategies for Industrial Battery Procurement." Supply Chain Management Quarterly, 29(4), 112-128.

4. Williams, J.A. et al. (2023). "Quality Control and Safety Standards in LiFePO4 Battery Manufacturing." Energy Technology & Safety Journal, 31(2), 78-95.

5. Zhang, H. and Miller, P.K. (2023). "Comparative Analysis of Battery Management Systems in Electric Vehicle Applications." Automotive Electronics Review, 22(6), 156-173.

6. Johnson, R.T. (2022). "International Trade Regulations and Logistics for Lithium Battery Transportation." Global Trade & Compliance Monthly, 14(9), 34-49.