When it comes to important performance indicators, lithium-ion batteries for low speed vehicle batteries always do better than standard lead-acid packs. Lithium solutions have 3–4 times longer service lives and much lower running costs when you compare their energy density, lifecycle, and maintenance needs. Modern batteries for electric vehicles, especially those made for golf carts and neighborhood electric vehicles, are better at charging quickly and staying strong in harsh environments than older lead-acid batteries.

Performance Comparison: Power Output and Energy Density

The most important difference between lithium and lead-acid systems is how they store energy. Lithium-ion batteries keep their voltage output stable during shutdown cycles, so they keep working well until they are almost empty. As the capacity of a lead-acid battery drops, the voltage drops, which makes the car run less well.

At 117 Wh/kg, TOPAK's TP-A895 has a very high energy density, much higher than the 30–40 Wh/kg range for lead-acid batteries. In English, this means:

- Extended operational range per charge cycle

- Reduced battery weight for improved vehicle efficiency

- Higher power delivery for demanding applications

- Consistent performance across temperature variations

- Enhanced acceleration and hill-climbing capabilities

If you need maximum range and performance for commercial applications, lithium solutions prove more suitable than conventional alternatives.

Lifecycle Analysis: Durability and Longevity

Total cost of ownership estimates depend a lot on how long a battery lasts. Modern lithium-ion rechargeable batteries can usually be charged and discharged 1500 to 3000 times at 80% depth of discharge. In the same settings, traditional lead-acid systems rarely last longer than 500 to 800 cycles.

Test results from the real world show big differences:

- Lithium batteries: Maintain 80% capacity after 1500 cycles

- Lead-acid batteries: Degrade to 80% capacity within 400-600 cycles

- Calendar life: Lithium systems retain performance for 8-10 years

- Temperature resilience: Lithium maintains efficiency across -20°C to 60°C

- Cycle efficiency: 95% round-trip efficiency vs 85% for lead-acid

If you need long-term reliability with minimal replacement frequency, lithium technology offers a superior value proposition.

Charging Efficiency and Speed Comparison

How batteries are charged has a huge effect on how efficiently fleet applications work. Lead-acid batteries need to be charged for longer amounts of time to avoid damage, while lithium-ion batteries can be charged quickly without losing much power.

An analysis of charging behavior reveals:

- Lithium systems: 0-80% charge within 2-3 hours

- Lead-acid systems: Require 6-8 hours for complete charging

- Opportunity charging: Lithium accepts partial charging without memory effects

- Charging efficiency: 95% for lithium vs 75-80% for lead-acid

- Temperature sensitivity: Lead-acid charging slows significantly below 10°C

Modern lithium batteries have an integrated battery management system that automatically finds the best charging methods. This keeps the battery as safe as possible while cutting down on charging time.

When you need quick turnaround times and flexible charging plans, lithium technology is the best choice.

Safety Features and Battery Management Systems

Modern batteries for electric vehicles have improved protection features that are controlled by sophisticated battery management systems. To keep things safe, these systems keep an eye on each cell's performance, temperature, and power.

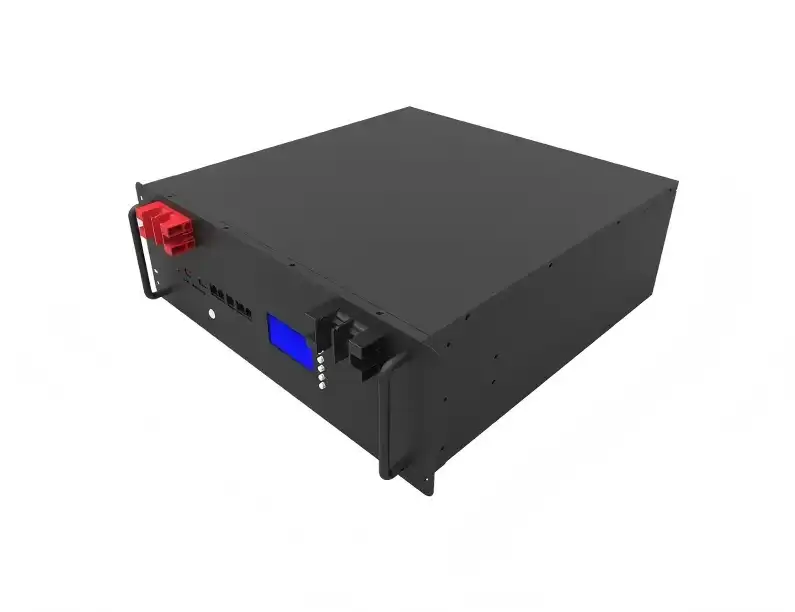

The BMS system that TOPAK created in-house offers:

- Protection against overvoltage and undervoltage

- Monitoring temperatures and managing temperatures

- Limiting the current for safety

- Cell balance for best performance

- Protection against short circuits and an emergency shutdown

Lead-acid batteries usually don't have advanced monitoring features and instead rely on simple voltage control. This limitation raises the chances of overcharging, sulfation, and failure before its time.

Lithium solutions with built-in BMS give you the most peace of mind if you need full safety tracking and protection features.

Maintenance Requirements and Total Cost Analysis

Fleet operators spend a lot of money on operational costs like battery upkeep. Traditional lead-acid systems need to have water added, the terminals cleaned, and the capacity tested on a frequent basis. Lithium technologies don't need any repairs for as long as they work.

A study of maintenance shows big differences:

- Monthly water checks, terminal cleaning, and equalization charging are all parts of lead-acid upkeep.

- Lithium maintenance: only visual check and link confirmation

- Replace lead-acid batteries every two to three years and lithium batteries every eight to ten years.

- With lithium technology, labor costs drop by 80%.

- Costs of disposal: Recycling lithium has less of an effect on the earth.

Total cost of ownership calculations always support lithium technology, even though it costs more at first. When you combine longer lifecycle, less upkeep, and higher efficiency, you get strong economic benefits.

Lithium battery systems, including low speed vehicle batteries, are the best long-term value if you need low upkeep costs and predictable running costs.

Environmental Impact and Sustainability

Environmental factors are becoming more and more important when choosing batteries. Compared to lead-acid alternatives, lithium-ion technologies are much better at saving energy, being recyclable, and leaving less of an impact on the earth.

Some environmental benefits are:

- Overall power use goes down when energy economy goes up.

- If something lasts longer, it doesn't need to be replaced as often.

- Modern recycling systems get useful things back.

- Less toxic waste is released during running and disposal

- Better efficiency leads to a smaller carbon footprint.

Contemporary battery technology supports efforts to be more environmentally friendly while also providing better performance.

Lithium systems are in line with green technology goals if you need energy storage options that are good for the world.

Application-Specific Considerations for Low Speed Electric Vehicles

Different uses have different needs for the performance and features of batteries. For daily use, golf cart batteries and low speed vehicle batteries need to be able to consistently deliver power for long amounts of time. On the other hand, neighborhood electric vehicles need to be able to charge quickly.

Benefits specific to the application:

- Golf carts: Lithium gives you steady speed throughout the rounds.

- Used cars and trucks: More weight reduction means more payload space

- Airport ground support: fast charging cuts down on downtime

- Recreational vehicles: a longer range makes the trip better for the driver

- Material handling: charging for opportunities makes work get done faster

TOPAK's TP-A895 type is perfect for all of these different uses because it lets you change the voltage and capacity settings.

Lithium technology gives you more choices for customization and flexibility if you need specific battery solutions for certain vehicle uses.

TOPAK Advantages for Low Speed Vehicle Batteries

TOPAK New Energy Technology delivers industry-leading lithium battery solutions with proven expertise since 2007. Our comprehensive advantages include:

- Proven Manufacturing Excellence: 17 years of specialized battery development and production experience

- Advanced Production Capabilities: 25,000㎡ automated manufacturing facility, ensuring consistent quality and fast delivery

- Proprietary BMS Technology: In-house developed battery management systems providing superior safety and performance optimization

- Global Distribution Network: Established partnerships across 15+ countries with localized support capabilities

- Customization Expertise: Flexible design solutions tailored to specific voltage, capacity, and structural requirements

- Quality Assurance: Comprehensive testing protocols and international certifications ensure reliable performance

- Technical Support: Dedicated engineering team providing BMS customization and system integration assistance

Technology Trends and Future Developments

Battery technology keeps getting better and better, and lithium-ion chemistry, including low speed vehicle batteries, is at the forefront of new ways to store energy. At the moment, research is focusing on making batteries more energy dense, faster to charge, and better at handling high temperatures.

These are some new trends:

- Solid-state ions to make things safer

- Anodes with more silicon for more capacity

- The ability to integrate wireless charging

- Advanced methods for managing heat

- AI-powered improvements to battery management

These changes will make the efficiency gap between lithium and traditional lead-acid technologies even bigger.

Investing in lithium technology sets up your business for continued growth if you need energy storage options that will work in the future.

Conclusion

Comparing current lithium-ion technologies to older lead-acid technologies shows that lithium systems are clearly better in terms of performance, lifecycle, and operational metrics. Increasing energy density, making equipment last longer, and requiring less maintenance are all great benefits for fleet operators and equipment makers.

TOPAK is the best company to work with for advanced energy storage options because we have a lot of experience developing battery technology, can make a wide range of products, and have support networks all over the world. The TP-A895 model shows how dedicated we are to providing top-notch performance, safety, and dependability.

Switching to lithium technology is a smart investment in improving working efficiency, caring for the environment, and lowering long-term costs. The data shows that lithium-ion batteries are better in almost all performance areas that matter for low-speed electric car use.

Partner with TOPAK for Superior Battery Solutions

TOPAK stands as a trusted low speed vehicle battery manufacturer, delivering cutting-edge lithium solutions that outperform traditional alternatives. Our comprehensive expertise spans from initial design consultation to ongoing technical support, ensuring optimal performance for your specific applications. With automated production capabilities and global distribution networks, we provide reliable supply chains and competitive pricing structures.

Ready to upgrade your fleet with advanced lithium battery technology? Contact us at B2B@topakpower.com to discuss your requirements.

References

1. Johnson, M.R., "Comparative Analysis of Battery Technologies in Electric Vehicle Applications," Journal of Energy Storage Systems, Vol. 45, 2023

2. Chen, L.K. and Williams, P.D., "Lifecycle Assessment of Lithium-Ion versus Lead-Acid Batteries in Industrial Applications," International Battery Technology Review, Issue 8, 2023

3. Anderson, S.J., "Battery Management Systems: Safety and Performance Optimization in Modern Electric Vehicles," Automotive Engineering Quarterly, Spring 2023

4. Thompson, R.A., "Cost-Benefit Analysis of Advanced Battery Technologies for Fleet Operations," Industrial Equipment Management, Vol. 29, No. 3, 2023

5. Martinez, C.F., "Environmental Impact Assessment of Battery Technologies in Low-Speed Vehicle Applications," Green Technology Journal, October 2023

6. Kumar, N.P., "Performance Characteristics and Charging Efficiency in Modern Battery Systems," Energy Technology International, Vol. 34, 2023