It is necessary to do a thorough analysis of the technical skills, manufacturing knowledge, and long-term support commitments of potential partners in order to select the most suitable c&i energy storage partner. Performance that is robust, solutions that can be customized, and reliability that has been demonstrated across a variety of operational settings are all requirements for commercial and industrial energy storage systems. In order to support your energy infrastructure ambitions, the ideal partner will combine cutting-edge technology for battery management systems, production capacity that can be scaled up, and extensive service networks. Organizations are able to make more educated decisions that improve their operational efficiency and lower their total cost of ownership when they have a thorough understanding of the major selection criteria.

Understanding Your C&I Energy Storage Requirements

c&i energy storage presents a unique set of issues for commercial and industrial applications, which necessitates the development of individualized solutions. Manufacturing facilities require uninterrupted power for crucial production lines, whereas data centers require backup systems with response times measured in milliseconds. Solar energy integration projects require systems that are capable of handling up to 46.2 kilowatts of solar input and have the capacity to reach a maximum open-circuit voltage of around 1500 volts.

There is a large amount of variation in energy density considerations between applications. The producers of industrial equipment are looking for lithium-ion battery systems that are optimized for activities such as robotic systems, automated guided vehicles, and forklift operations. These applications require a high cycle life performance, which typically exceeds 6,000 charge-discharge cycles while retaining a capacity retention rate of 80 percent.

Battery systems must be able to function in temperatures ranging from -20 degrees Celsius to 60 degrees Celsius in order to support the infrastructure of telecommunications. Thermal management is essential for ensuring that base station installations are able to maintain an optimal state of charge and prevent capacity fade. Base station installations frequently face demanding environmental circumstances of this kind.

Ensure that the requirements of the power conversion system are in line with the electrical infrastructure of the facility. While providing grid stabilizing capabilities, systems that generate 32 kilowatts of alternating current (AC) output and have broad operating ranges of 220 volts to 230 volts are able to serve a wide variety of commercial applications.

Technical Capabilities and Manufacturing Excellence

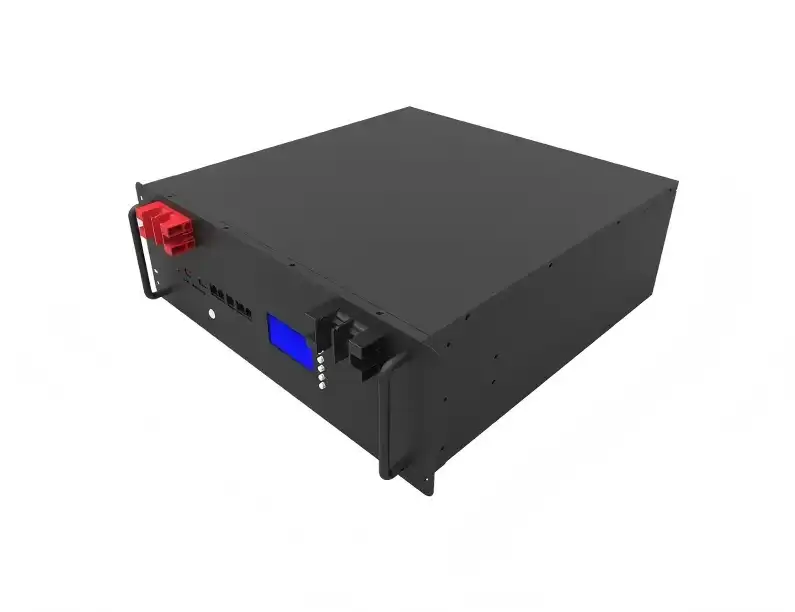

The technology behind advanced battery management systems is what differentiates leading c&i energy storage partners from traditional vendors. The construction of a BMS in-house offers greater safety protocols, enhanced performance optimization, and the ability to integrate systems in a smooth manner. Exclusive to TOPAK, the Battery Management System (BMS) technology provides accurate monitoring of the voltages, temperatures, and current flows of individual cells.

Production lines that are automated on a large scale ensure that the quality is consistent while also allowing for faster delivery schedules. In addition to reducing the likelihood of human mistake, automated manufacturing procedures also help to maintain tight tolerance controls and support scalable production quantities. These characteristics prove to be indispensable in situations when the fast deployment of energy storage infrastructure is required to meet project timeframes.

By utilizing multiple MPPT channels, the efficiency of renewable integration can be optimized. The potential for solar energy harvesting is maximized by systems designed with six separate maximum power point tracking controllers, voltage ranges ranging from 125 to 425 volts, and maximum current capacity of 26 amps per channel. In a wide range of weather circumstances, this setup makes it possible to implement energy dispatch strategies that are optimal.

Recent developments in inverter technology have improved both the power quality and the possibilities of grid interfacing. In order to improve the overall performance of the system, modern systems contain features like as frequency regulation, demand response functionality, and sophisticated load balancing algorithms.

Safety Standards and Certification Requirements

Complying with international certification standards guarantees that operational safety and accessibility to global markets are maintained. Certifications covering electrical safety, electromagnetic compatibility, and environmental performance criteria are required for energy storage devices with the capability to store energy. Through these certifications, the reliability of the system is validated across a variety of installation settings.

The degeneration of batteries is prevented by thermal management systems, which also ensure that safe operating temperatures are maintained. Both passive and active thermal control techniques are incorporated into advanced cooling strategies. These mechanisms extend the cycle life of the system and reduce the amount of maintenance that is required.

Safety concerns in commercial installations are addressed by the integration of fire suppression strategies. Battery enclosures of today come equipped with built-in fire detection systems, automatic suppression mechanisms, and emergency shutdown protocols, all of which serve to safeguard persons and equipment.

Ground faults are avoided and shock hazards are minimized thanks to electrical isolation requirements, which are implemented during maintenance operations. It is possible to perform safe servicing procedures while retaining system availability during routine inspections if the configuration of the isolator is designed correctly.

Customization Flexibility and Engineering Support

Companies that integrate c&i energy storage systems need to have flexible design alternatives that can accommodate the requirements of specific projects. Mechanical form factors, capacity scaling choices, and custom voltage settings all make it possible to achieve optimal integration with the infrastructure that is already in place. Certain combinations of voltage levels and amp-hour ratings are frequently required in order to fulfill the standards for battery storage capacity.

There are particular monitoring and control requirements that can be addressed by the customization possibilities of BMS. It may be necessary for industrial applications to have individualized communication protocols, particular alarm thresholds, or interaction with systems that are already in place for facility management. Technical support is provided by engineering teams throughout the design phase, which helps to ensure that the system configuration is chosen optimally.

In the future, expansion and maintenance processes will be easier to perform with modular architecture. In addition to simplifying the management of spare parts inventories, systems that are constructed with standardized components make it possible to enhance capacity at significantly reduced costs.

The original equipment manufacturers can benefit from the full design services provided by ODM collaborations. As a result of these collaborations, product development durations are accelerated. These collaborations include the optimization of mechanical design, support for electrical integration, and assistance with regulatory compliance.

Global Distribution and Service Networks

The capacity to provide service on a global scale guarantees consistent support regardless of the location of the installation. Localized technical assistance is provided by partners who have created distribution networks that cover more than 15 countries. This helps to reduce response times and improve customer satisfaction.

Delivery delays are kept to a minimum and logistics expenses are cut down thanks to regional inventory management. The positioning of warehouses in strategic areas allows for the rapid availability of parts while simultaneously maintaining competitive pricing structures for replacement components.

Training programs for technicians ensure that the installation and maintenance processes are carried out correctly. Professional installation services, support for routine maintenance, and emergency repair capabilities are all provided by certified technician networks, which help to maximize the amount of time that a system is operational.

Through the use of remote monitoring capabilities, proactive maintenance scheduling and performance optimization are made possible. Cloud-based monitoring tools offer real-time system status updates, alerts for preventative maintenance, and thorough performance statistics, all of which are designed to support energy arbitrage techniques.

Long-term Partnership Value and Cost Optimization

Partnerships with well-established manufacturers who have demonstrated their track record of success give greater stability. Those businesses that have been in operation since 2007 have market resilience and have amassed experience, both of which contribute to the success of long-term projects. Because of this experience, supply chains that are reliable, product quality that is consistent, and service networks that are established are all formed.

Capabilities which are at their peak Charge-discharge cycling can be used strategically to cut down on the energy costs of the facility. Intelligent energy management systems automatically optimize patterns of energy usage, thereby lowering demand costs while simultaneously supporting the fulfillment of operational requirements.

The ability to do predictive maintenance and the design of components that are reliable both contribute to a reduction in maintenance costs. In addition to delivering extended operational lifespans that improve total cost of ownership estimates, high-quality lithium-ion battery systems require no routine maintenance and require only a limited amount of maintenance.

For the purpose of providing financial protection against capacity decline, performance guarantees are offered. In order to safeguard their customers' investments, leading manufacturers provide warranty terms that cover cycle life performance, capacity retention requirements, and system availability measures.

Conclusion

Choosing the right energy storage partner requires evaluating technical capabilities, manufacturing quality, and long-term support commitments. Successful partnerships combine advanced battery technology, flexible customization options, and comprehensive service networks that address evolving commercial and industrial energy requirements. TOPAK's proven expertise, proprietary BMS technology, and global distribution capabilities position us as the ideal partner for your energy storage initiatives. Our commitment to quality, innovation, and customer success ensures reliable performance across diverse applications while providing the technical support necessary for long-term operational excellence.

Partner with TOPAK for Superior C&I Energy Storage Solutions

TOPAK delivers comprehensive c&i energy storage solutions backed by 17 years of manufacturing excellence and proven industry expertise. Our automated production facilities, proprietary BMS technology, and global distribution network support diverse commercial and industrial applications worldwide. As a leading c&i energy storage manufacturer, we provide customizable battery systems ranging from 64.3KWh installations to large-scale grid applications with full technical support and certification compliance. Ready to optimize your energy infrastructure? Contact us at B2B@topakpower.com to discuss your project requirements.

References

1. International Energy Agency. "Commercial and Industrial Energy Storage Market Analysis Report 2024." Global Energy Storage Database, March 2024.

2. Battery Industry Association. "Guidelines for C&I Energy Storage System Selection and Implementation." Technical Standards Publication, 2024.

3. Renewable Energy Council. "Best Practices for Industrial Energy Storage Partner Evaluation." Industry White Paper Series, February 2024.

4. Commercial Energy Users Association. "Total Cost of Ownership Analysis for Large-Scale Battery Systems." Economic Impact Study, 2024.

5. Industrial Power Systems Journal. "Battery Management System Technologies in Commercial Applications." Technical Review Volume 45, Issue 3, 2024.

6. Energy Storage Technology Institute. "Certification Requirements for Commercial and Industrial Battery Systems." Compliance Guidelines Manual, January 2024.