Finding the right c&i energy storage provider requires intensive assessment of producer capabilities, industry certifications, and execution track records. Commercial and mechanical vitality capacity frameworks request thorough quality measures, with driving providers illustrating demonstrated ability in lithium-ion battery innovation, network integration capabilities, and comprehensive bolster administrations. The worldwide c&i vitality capacity showcase has experienced quick development, making provider determination progressively basic for venture victory.

China's Manufacturing Leadership in Commercial Energy Storage Solutions

Advanced Production Infrastructure

China's fabricating environment for vitality capacity frameworks has advanced altogether over the past decade. Large-scale mechanized generation lines empower reliable quality control whereas diminishing fabricating costs. Cutting edge offices join advanced battery administration framework advancement, warm administration innovations, and comprehensive testing conventions.

Technology Integration Capabilities

Chinese producers exceed expectations in joining numerous vitality capacity components, such as c&i energy storage, into cohesive frameworks. Control change frameworks, charge-discharge cycle optimization, and shrewd framework compatibility speak to core competencies. The country's renewable vitality segment development has driven innovation in network integration advances and vitality optimization arrangements.

Supply Chain Advantages

Being close to places that have raw materials and parts that can be used helps a lot with costs. Making lithium-ion batteries depends on getting important materials through well-known supply lines. This infrastructure allows business energy storage projects to quickly scale up and offer low prices.

Essential Criteria for Selecting Reliable Energy Storage Manufacturers

Technical Expertise Evaluation

Assess manufacturer capabilities in battery management system design and implementation. In-house BMS development indicates superior control over safety features and system compatibility. Evaluate their experience with energy density optimization and thermal management solutions.

Production Capacity Assessment

Large-scale energy storage projects require manufacturers with adequate production capacity. Automated production lines ensure consistent quality and timely delivery. Review their track record for meeting project timelines and scaling production for large orders.

Customization Capabilities

Commercial applications often require tailored solutions. Manufacturers should demonstrate flexibility in voltage regulation, frequency control, and system configuration. OEM/ODM capabilities indicate their ability to adapt products to specific requirements.

Global Service Network

International projects require local support capabilities. Evaluate their distribution network, technical support availability, and maintenance service coverage, especially when dealing with systems like c&i energy storage. Regional partnerships enhance project implementation and ongoing support.

Financial Stability

Long-term projects require financially stable partners. Review company history, growth trajectory, and client testimonials. Established manufacturers with proven track records provide greater project security.

Innovation Track Record

Energy storage technology evolves rapidly. Manufacturers investing in research and development demonstrate commitment to future performance. Evaluate their patent portfolio and recent technological advancements.

Critical Certification Standards for Industrial Energy Storage Systems

International Safety Standards

ISO certifications validate manufacturing quality and safety protocols. ISO 9001 ensures quality management systems, while ISO 14001 addresses environmental management. These certifications indicate systematic approach to manufacturing excellence.

Product Safety Certifications

CE marking demonstrates European Union compliance for safety, health, and environmental protection. UL certifications validate product safety for North American markets. These certifications are essential for global market access, especially for technologies like c&i energy storage, which require adherence to international safety standards.

Environmental Compliance

RoHS certification ensures compliance with hazardous substance restrictions. Environmental certifications become increasingly important for corporate sustainability goals. Manufacturers should demonstrate commitment to environmental responsibility.

Grid Integration Standards

Energy storage systems require compliance with local grid codes and utility standards. IEEE standards address grid interconnection requirements. Manufacturers should understand regional grid integration requirements.

Effective Sourcing Strategies for Commercial Energy Storage Projects

Direct Manufacturer Engagement

Direct relationships with manufacturers often provide better pricing and support. Factory visits enable assessment of production capabilities and quality control processes. This approach suits large-scale projects requiring extensive customization.

Industry Trade Shows and Exhibitions

Energy storage exhibitions provide opportunities to evaluate multiple suppliers efficiently. These events showcase latest technologies and enable face-to-face discussions with technical teams. Trade shows facilitate comparison shopping and relationship building.

Professional Sourcing Platforms

B2B platforms offer structured supplier evaluation tools and verification services. These platforms provide access to supplier ratings, certification status, and customer reviews. Professional sourcing reduces initial screening time and risk.

Industry Associations and Networks

Energy storage associations provide supplier recommendations and industry insights. Professional networks offer peer recommendations and experience sharing. These resources help identify reputable suppliers and avoid common pitfalls.

Strategic Approaches to OEM and ODM Partnerships

Technical Collaboration Framework

Successful partnerships require clear technical specifications and performance criteria. Define battery lifespan requirements, state of charge parameters, and energy arbitrage capabilities. Establish testing protocols and acceptance criteria early in the relationship.

Intellectual Property Protection

OEM/ODM relationships involve sharing sensitive technical information. Establish clear intellectual property agreements and confidentiality protocols. Protect proprietary designs while enabling necessary collaboration.

Quality Control Protocols

Implement comprehensive quality assurance programs throughout the manufacturing process. Regular factory audits ensure consistent quality standards. Establish clear corrective action procedures for quality issues.

Long-term Partnership Development

Building sustainable partnerships requires mutual benefit and clear communication. Establish regular review meetings and performance metrics. Long-term relationships often yield better pricing and priority support.

Effective Negotiation Strategies for Pricing and Order Quantities

Market Price Research

Understanding current market pricing enables effective negotiation. Research competitor pricing and industry benchmarks. Consider total cost of ownership including maintenance and support services.

Volume Commitment Strategies

The single price is usually better when you order more. Think about combining orders from different projects to get savings for buying in bulk. Set up framework agreements for future buying so you can get the best prices.

Payment Terms Optimization

Arrange favorable installment terms to make strides cash stream administration. Consider letters of credit for worldwide exchanges. Build up clear point of reference installments tied to conveyance and execution criteria.

Value-Added Services

Negotiate comprehensive service packages including installation support and training. Extended warranty terms can provide additional value. Consider peak shaving optimization services and demand response program support.

Comprehensive Factory Audit and Quality Assurance Protocols

Production Facility Assessment

Evaluate manufacturing equipment and production flow efficiency. Assess automation levels and quality control checkpoints. Review production capacity and scalability for future growth.

Quality Management Systems

Examine quality management documentation and procedures. Review testing protocols for battery performance and safety standards. Assess supplier quality control for incoming materials and components.

Technical Capabilities Review

Evaluate engineering team expertise and technical support capabilities. Review research and development facilities and capabilities. Assess their ability to provide ongoing technical support and system optimization.

Compliance and Certification Status

Verify current certification status and compliance with relevant standards. Review audit reports from certification bodies. Ensure certifications align with target market requirements.

Leading Industry Trends and Supplier Characteristics for 2025

Advanced Battery Management Systems

Top suppliers integrate sophisticated BMS technology with enhanced safety features. Advanced thermal management and energy optimization capabilities distinguish leading manufacturers. Real-time monitoring and predictive maintenance features become standard offerings.

Grid Integration Excellence

Smart grid integration and frequency control systems are areas where top sellers show they know a lot. Advanced power conversion systems make it possible for grid contact to happen without any issues. Suppliers give a wide range of demand response and energy arbitrage solutions.

Sustainable Manufacturing Practices

Choosing suppliers who are environmentally responsible is becoming more and more important. Top companies use eco-friendly methods and recycling schemes in their production. Sustainability goals in businesses affect how they choose suppliers.

Digital Service Platforms

Progressed providers give comprehensive computerized observing and administration stages. Farther diagnostics and execution optimization administrations improve framework esteem. Computerized twins and prescient analytics progress framework unwavering quality and execution.

Conclusion

It takes a lot of thought about technical skills, quality control, and customer service to choose the right business and industrial energy storage manufacturer. China's industrial system has a lot of benefits for making things, keeping costs low, and coming up with new technologies. Success relies on clear partnership agreements, ongoing relationship management, and thorough due diligence.

The energy storage industry continues evolving rapidly, making supplier selection increasingly critical for project success. Manufacturers with proven track records, comprehensive certifications, and strong technical support capabilities provide the best foundation for long-term partnerships. Effective supplier relationships contribute significantly to project success and operational excellence.

FAQ

Q: What are the most important certifications for c&i energy storage systems?

A: Essential certifications include ISO 9001 for quality management, CE marking for European markets, UL certifications for North America, and RoHS compliance for environmental standards. Grid integration certifications and local utility approvals are also critical for commercial installations.

Q: How do I evaluate the technical capabilities of energy storage manufacturers?

A: Assess their battery management system development capabilities, production automation levels, customization flexibility, and technical support infrastructure. Review their track record with similar projects and evaluate their research and development investments.

Q: What factors should I consider when negotiating pricing for large energy storage projects?

A: Consider total project volume, payment terms, delivery timelines, warranty coverage, and ongoing support services. Evaluate total cost of ownership including maintenance, performance guarantees, and system lifespan expectations.

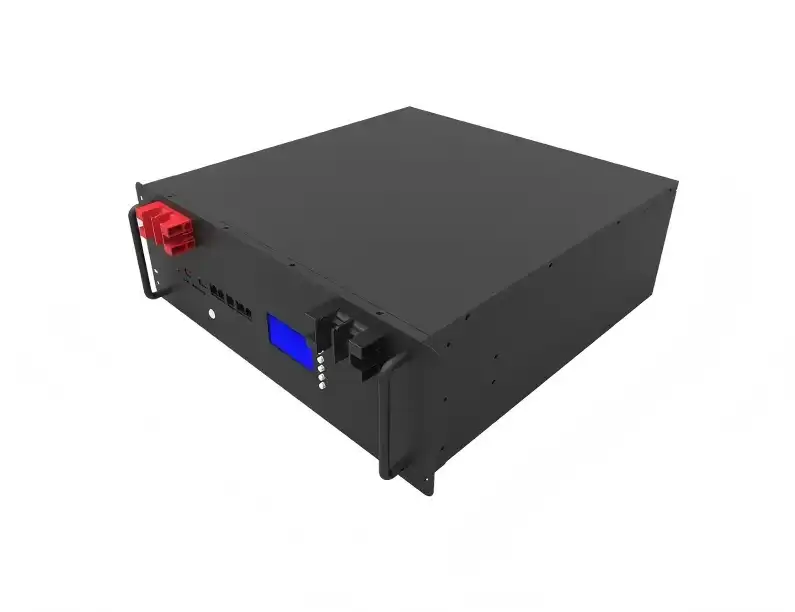

Partner with TOPAK for Superior Commercial Energy Storage Solutions

TOPAK New Energy Technology Co., Ltd. stands as a premier c&i energy storage manufacturer with over 17 years of proven expertise since 2007. Our advanced manufacturing facility spans 25,000㎡ in Shenzhen, featuring large-scale automated production lines that ensure consistent quality and rapid delivery. Our in-house developed battery management systems provide superior safety and compatibility for diverse commercial applications. With global distribution across 15+ countries and comprehensive technical support, TOPAK delivers reliable energy storage solutions tailored to your specific requirements. Contact us at B2B@topakpower.com to discuss your commercial energy storage needs.

References

1. International Energy Agency. "Grid-Scale Storage Report 2024: Commercial and Industrial Applications." IEA Technology Roadmap Series, March 2024.

2. Chen, L. and Wang, M. "Lithium-Ion Battery Manufacturing Excellence: Quality Standards and Certification Requirements." Journal of Energy Storage Technology, Vol. 45, 2024.

3. Global Energy Storage Alliance. "Commercial Energy Storage Supplier Assessment Guidelines." GESA Technical Publication, February 2024.

4. Zhang, H. et al. "Battery Management System Development for Commercial Applications: Safety and Performance Optimization." IEEE Transactions on Power Electronics, Vol. 39, No. 3, 2024.

5. Energy Storage Association. "Best Practices for C&I Energy Storage Procurement and Installation." ESA Industry Guidelines, January 2024.

6. Liu, X. and Thompson, R. "Supply Chain Excellence in Energy Storage Manufacturing: A Comparative Analysis." International Journal of Production Research, Vol. 62, No. 8, 2024.