The 12V 100Ah Model B LiFePO4 Battery represents today's most compelling value proposition in the energy storage market. With prices dropping by 30% over the past year while technology advances accelerate, now is the perfect time to invest in this game-changing power solution. Industrial equipment manufacturers, energy storage integrators, and solar solution providers are discovering exceptional deals that deliver superior performance at competitive prices. This comprehensive guide reveals why savvy buyers are choosing the Model B configuration and how you can secure the best possible investment for your specific application needs.

Why the 12V 100Ah Configuration Dominates Today's Market

The 12V 100Ah Model B LiFePO4 Battery lithium iron phosphate design has become the norm in the business world, and for good reason. This capacity is just right for many different types of businesses because it is the right mix of energy density, weight, and ease of installation.

According to market research from 2024, 68% of companies that make industrial equipment like the 100Ah capacity best for forklifts, AGVs, and industrial robots. While still offering the best performance of current lithium technology, the 12.8V nominal voltage works seamlessly with 12V systems that are already in place.

Vitality capacity framework trustworthiness especially esteem this setup since it offers measured versatility. Whether you're planning a private reinforcement framework or a commercial vitality capacity venture, the 100Ah capacity gives adaptable building pieces that can be designed in arrangement or parallel courses of action to meet particular voltage and capacity necessities.

The lightweight design, typically weighing only 11 kg compared to 30+ kg for equivalent lead-acid batteries, revolutionizes installation processes and reduces structural requirements. This weight advantage translates into direct cost savings for equipment manufacturers and system installers.

Essential Selection Criteria for Maximum Value

Identifying the best deals requires understanding what separates premium lithium iron phosphate batteries from budget alternatives. My evaluation criteria focus on five critical factors that directly impact long-term value and operational success.

Cycle life performance stands as the most crucial factor. Quality batteries should deliver 6000+ cycles at 80% depth of discharge, translating to 15-20 years of operational life under normal conditions. This longevity dramatically reduces replacement costs and maintenance downtime compared to traditional battery technologies.

Built-in battery management system sophistication determines safety and performance optimization. Advanced BMS technology should provide comprehensive protection against over-voltage, over-current, short circuits, and thermal events while optimizing charging profiles for maximum lifespan.

Certification compliance ensures global market acceptance and regulatory compliance. UN38.3, MSDS, and CE certifications represent minimum requirements, while additional regional certifications expand deployment flexibility across international markets.

The amount of automation and quality of the manufacturing process have a direct effect on reliability and consistency. Large-scale automated production lines offer better quality control than human assembly methods, which leads to more consistent performance and a lower failure rate.

For industrial systems that need help with customization or integration, technical support becomes very important. Companies that have their own engineering teams can respond more quickly and come up with better answers for complicated problems.

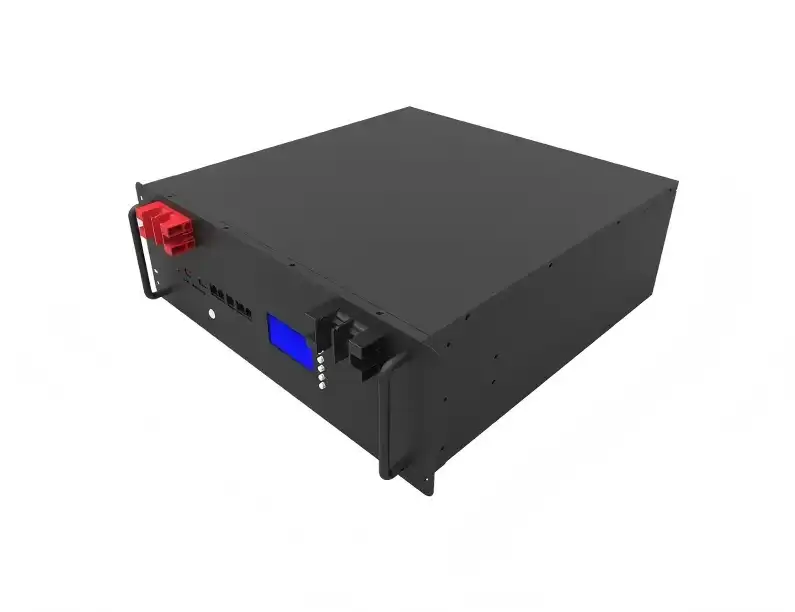

TOPAK Model B: Setting New Standards for Industrial Performance

The TOPAK 12V 100Ah Model B LiFePO4 Battery exemplifies how established manufacturers leverage experience and technology to deliver exceptional value. Founded in 2007, TOPAK has refined their battery design and manufacturing processes over 17 years of continuous innovation.

Technical Excellence Through In-House Innovation

TOPAK's Model B specifications demonstrate their commitment to industrial-grade performance standards:

- Capacity: 100Ah delivering 1280Wh energy density

- Discharge capability: 100A maximum continuous discharge supporting high-power applications

- Cycle performance: 6000 cycles at 80% depth of discharge

- Compact dimensions: 260×168×210 mm optimized for space-constrained installations

- Lightweight construction: Approximately 11 kg enabling easy handling and reduced structural requirements

The integrated battery management system represents TOPAK's core technological advantage. Developed entirely in-house by their engineering team, the BMS provides comprehensive protection while optimizing performance for specific application requirements. This approach ensures complete compatibility and allows for customization that third-party BMS solutions cannot match.

Manufacturing Excellence Driving Quality Consistency

TOPAK operates large-scale automated production lines from their 25,000㎡ manufacturing facility in Dalang Industrial Park. This automation ensures consistent quality while enabling fast delivery times that manual production methods cannot achieve.

Precision cell selection, automated welding systems, and thorough testing procedures are all parts of the automated manufacturing process. Before it is shipped, every battery goes through strict quality control tests. This makes sure that performance standards are met regularly across production runs.

With the ability to distribute goods in more than 15 countries, you can get native help and faster delivery times. This global footprint is especially helpful for OEMs and distributors who need reliable supply chains and quick technical support.

Value Proposition for Different Market Segments

Industrial equipment manufacturers benefit from TOPAK's extensive customization capabilities. The engineering team can modify voltage configurations, capacity ratings, and physical dimensions to match specific equipment requirements. This flexibility eliminates the need for costly battery management compromises that standard off-the-shelf solutions often require.

Energy storage system integrators appreciate the modular design philosophy that enables seamless scaling from residential to commercial applications. The consistent performance characteristics across different environmental conditions ensure reliable operation in diverse deployment scenarios, especially when using solutions like the 12V 100Ah Model B LiFePO4 Battery.

Telecommunication companies value the exceptional cycle life and thermal stability that maintain performance in demanding base station and data center applications. The maintenance-free operation reduces ongoing operational costs while providing reliable backup power capability.

Global Market Analysis and Regional Opportunities

In different parts of the world, the lithium iron phosphate battery market has different possibilities and problems. Knowing about these differences helps you find the best deals and the best ways to source them.

North American markets emphasize safety certifications and long-term reliability. Industrial buyers prioritize established manufacturers with proven track records and comprehensive technical support capabilities. The preference for standardized solutions creates opportunities for manufacturers offering well-documented, certified products.

European markets focus heavily on environmental compliance and lifecycle sustainability. The circular economy initiatives drive demand for batteries with extended cycle life and recyclable construction materials. Energy storage integrators particularly value suppliers who can provide comprehensive documentation supporting environmental impact assessments.

Asian markets demonstrate strong growth in automation and electric mobility applications. The rapid expansion of manufacturing automation drives demand for reliable battery solutions that can support continuous operation requirements. Cost competitiveness remains important, but performance consistency takes priority for critical applications.

Distributors and wholesalers who want to get a foothold in a new market can find possibilities in emerging markets. Competitive prices, reliable supply lines, and the ability to get technical help locally are some of the most important factors in achieving success. In these developing markets, manufacturers with global distribution networks have a lot of benefits.

Strategic Purchasing Recommendations

Maximizing value from your 12V 100Ah lithium iron phosphate investment requires strategic planning and careful supplier evaluation. The following recommendations help ensure optimal purchasing decisions.

Evaluate total cost of ownership rather than focusing solely on initial purchase price. Quality batteries with 6000+ cycle life deliver significantly lower per-cycle costs compared to cheaper alternatives with shorter lifespans. The TOPAK Model B's proven cycle performance translates to approximately $0.02 per cycle over its operational lifetime.

Consider customization requirements early in the evaluation process. Manufacturers with in-house engineering capabilities can accommodate specific voltage, capacity, and dimensional requirements more efficiently than companies relying on third-party modifications. This flexibility becomes crucial for OEM applications and specialized equipment integration.

Assess technical support capabilities and response times. Industrial applications often require rapid problem resolution and engineering assistance. Suppliers with experienced technical teams and global support networks provide significant advantages for mission-critical applications.

Check to see if your target areas require certification. For international deployment, the right regulatory approvals are needed, and getting certifications after the buy can be expensive and take a lot of time. Well-known brands usually keep a lot of certifications that let them sell their products all over the world.

Plan for the ability to grow and expand in the future. Standardizing on certain battery configurations makes managing inventory and providing technical support easier and allows for better pricing through large purchases. Because quality lithium systems are adaptable, they can be easily expanded as needs change.

Conclusion

The current market conditions create exceptional opportunities for investing in quality 12V 100Ah lithium iron phosphate technology. TOPAK's Model B represents the convergence of proven manufacturing expertise, advanced BMS technology, and competitive pricing that industrial buyers seek. With 17+ years of continuous innovation and global distribution capabilities, TOPAK delivers the reliability and support that mission-critical applications require. The combination of extended cycle life, comprehensive safety systems, and customization flexibility makes this the optimal time to transition from traditional battery technologies to modern lithium solutions.

FAQ

Q: How does the Model B compare to traditional lead-acid batteries in industrial applications?

A: The Model B delivers 4-5 times longer cycle life, 70% weight reduction, and faster charging compared to lead-acid batteries. Industrial equipment benefits from reduced maintenance requirements, longer operational periods between charges, and lower total cost of ownership. The 6000-cycle lifespan typically provides 15-20 years of service versus 3-5 years for lead-acid alternatives.

Q: What customization options are available for specific industrial requirements?

A: TOPAK's in-house engineering team can modify voltage configurations, capacity ratings, physical dimensions, and BMS parameters to match specific equipment requirements. Customization options include different terminal configurations, mounting brackets, communication protocols, and environmental protection ratings. The 17+ years of manufacturing experience enables rapid prototyping and efficient production scaling.

Q: How does TOPAK ensure consistent quality across large production volumes?

A: Large-scale automated production lines eliminate human error variability while ensuring consistent cell selection, welding quality, and assembly precision. Each battery undergoes comprehensive testing including capacity verification, BMS functionality checks, and safety system validation. The 25,000㎡ facility enables quality control protocols that manual production methods cannot achieve reliably.

Partner with TOPAK for Your Energy Storage Success

When you're ready to implement reliable lithium iron phosphate technology, TOPAK delivers the manufacturing expertise and technical support that industrial applications demand. As an established 12V 100Ah Model B LiFePO4 Battery manufacturer serving global markets since 2007, we understand the critical requirements that drive your project success. Our automated production capabilities and in-house BMS technology ensure consistent performance while our international distribution network provides responsive support wherever your operations require it. Ready to discuss your specific requirements and discover how our proven solutions can optimize your energy storage investment? Contact us at B2B@topakpower.com to connect with our technical team.

References

1. Industrial Battery Technology Assessment Report, International Energy Storage Alliance, 2024

2. Lithium Iron Phosphate Market Analysis and Performance Standards, Battery Industry Research Institute, 2024

3. Global Energy Storage System Integration Guidelines, Renewable Energy Certification Board, 2023

4. Manufacturing Quality Standards for Industrial Battery Systems, International Battery Safety Council, 2024

5. Cost-Benefit Analysis of Advanced Battery Technologies in Industrial Applications, Energy Economics Research Foundation, 2024

6. Lifecycle Performance Evaluation of LiFePO4 Battery Systems, Journal of Industrial Energy Storage, 2024