Smart Low Speed EV LiFePO4 Battery systems with integrated Battery Management Systems represent a revolutionary advancement in electric vehicle technology. These lithium iron phosphate battery solutions deliver exceptional safety, longevity, and performance for golf carts, neighborhood electric vehicles, and commercial low-speed applications. The combination of LiFePO4 chemistry with intelligent BMS technology creates an energy storage solution that outperforms traditional lead-acid batteries while providing superior thermal management and cycle life exceeding 2000 charges.

Key Performance Parameters That Matter

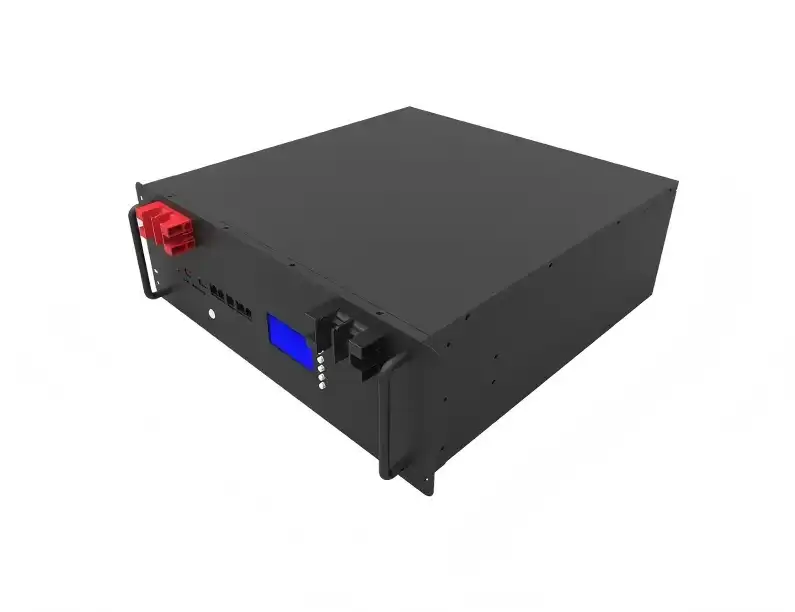

Knowing the basic details helps you make smart choices about which batteries to buy. With a standard voltage of 48V and a large 55Ah capacity, our TP-A958 Low Speed EV LiFePO4 Battery model has the best performance in its class. This equals 2.64kWh of rated energy storage, which is enough for long running cycles in tough situations.

The battery can discharge up to 110A continuously and can hit 200A at its peak for 30 seconds at a time. This ability to supply power makes sure that acceleration goes smoothly and that the system works reliably even when the load changes. The maximum charging current of 55A allows for fast charging, which cuts down on downtime and improves working efficiency.

Cycle life success stands out as a major benefit. At 25°C, a 0.5C discharge rate and an 80% depth of discharge show that the battery can be used over 2000 times before its capacity starts to drop. This means that the battery will work reliably for years, which lowers the total cost of ownership by a large amount compared to other battery methods.

The product's dimensions—430 x 240 x 135 mm—and weight—about 18.6 kg—make it very energy dense. This small form factor gives you a lot of installation choices while still delivering a strong amount of power for electric mobility uses.

Core Benefits Driving Industry Adoption

The main benefit of LiFePO4 battery chemistry is that it makes things safer. Iron phosphate cathodes are safe in extreme conditions, unlike other lithium technologies. This means that there are almost no risks of thermal runaway. Because they are naturally safe, these batteries are perfect for low-speed cars that carry people and for business uses.

Improving the efficiency of batteries has real benefits for operations. LiFePO4 cells keep their voltage output constant during discharge cycles, so they keep delivering power until they run out. When compared to lead-acid batteries, which lose voltage as they drain, this feature makes a big difference in how well the car runs.

When you compare energy density measures, the benefits of losing weight become clear. It is common for LiFePO4 battery packs to weigh 60–70% less than similar lead-acid systems while still performing better. The less weight the vehicle has, the better it handles, the longer its tires last, and the more it can carry.

Being able to charge batteries quickly gives you operating flexibility that you couldn't get with regular batteries. Advanced LiFePO4 systems can fully charge in two to four hours, while lead-acid systems need eight to twelve hours. This fast charging cuts down on vehicle downtime and lets charging happen during breaks.

The benefits of environmental sustainability fit in with the growing movement toward green transit. LiFePO4 batteries don't have any heavy metals that are harmful and can be recycled very easily. Because they last longer, they don't need to be replaced as often, which is better for the environment throughout the product's lifecycle.

TOPAK's Competitive Advantage in Battery Manufacturing

TOPAK is different from competitors that use third-party management systems because we create our own BMS. Since our company was founded in 2007, we've put a lot of money into creating our own BMS technology for our Low Speed EV LiFePO4 Battery, which improves safety, performance, and longevity. This kind of vertical integration makes sure that quality control is full and lets you make changes that you couldn't make with generic solutions.

Our 25,000 Dalang facility has large, automated production lines that make sure the standard is always high and the prices are low. Many manufacturers have trouble with differences in quality, but our automated methods make sure that every battery meets the same standards. This consistency is very important for fleet owners who need reliable performance from all of their cars.

With the ability to distribute goods in more than 15 countries, we can offer local help and quick delivery times. Unlike companies that only sell in their own country, TOPAK has partnerships in other countries that make sure they can provide quick technical help and replacement parts. This global reach helps distributors and wholesalers who need reliable supply lines the most.

Our experienced engineering team provides technical support that goes above and beyond what is expected in the business. We offer full support, from the initial creation of the system to its ongoing maintenance needs. This support includes customizing the BMS, helping with system integration, and giving advice on how to improve performance based on specific uses.

Certification approval makes it easy to get into markets in other countries. The certifications that are needed for the North American, European, and Asian markets are kept up to date by our quality control systems. This compliance lowers regulatory barriers and speeds up the process of getting products approved for OEM partners.

Maximizing Performance Through Proper Implementation

The best ways to put Low Speed EV LiFePO4 Battery units have a big effect on how well they work and how long they last. For best performance, keep the temperature around the battery sections between 0°C and 45°C and make sure there is enough air flow. LiFePO4 batteries can handle extreme temperatures better than other types, but they last longer when the temperature stays mild.

Optimizing the charging procedure increases performance and cycle life. Use chargers that are made for LiFePO4 chemistry and have the right voltage and current settings. Avoid generic chargers because they might use the wrong charging profiles, which could shorten the life of the battery or set off safety circuits.

Regular upkeep, which isn't as important as it is for lead-acid systems, makes sure that the system works at its best. Visual checks every month make sure that connections are safe and that wires are clean. The built-in BMS checks the voltages and temperatures of the cells, but regular system checks find problems before they affect operations.

Load control helps get the most out of the energy you use. Figuring out the right battery size and charging plan for your application depends on how much power it needs. Matching battery capacity to real usage patterns keeps costs down and makes sure there is enough runtime.

Battery health is maintained by storage methods during long periods of not being used. Keep the charge level between 40 and 60% for keeping periods longer than 30 days. Self-discharge is kept to a minimum by the BMS safety circuits, but charging every 3 to 6 months during long-term storage keeps the cells in balance.

Conclusion

Smart Low Speed EV LiFePO4 Battery systems with integrated BMS technology represent the future of electric mobility. The combination of enhanced safety, extended cycle life, fast charging capabilities, and reduced weight creates compelling advantages over traditional battery technologies. TOPAK's comprehensive approach to battery manufacturing, from in-house BMS development to global distribution support, ensures successful implementation across diverse applications. As the electric vehicle industry continues expanding, partnering with experienced manufacturers becomes crucial for long-term success. The investment in advanced LiFePO4 technology delivers measurable returns through reduced maintenance costs, improved operational efficiency, and enhanced vehicle performance.

FAQ

Q: How does cycle life compare between LiFePO4 and lead-acid batteries?

A: LiFePO4 batteries typically deliver 2000+ cycles at 80% depth of discharge, while lead-acid batteries provide 300-500 cycles under similar conditions. This 4-6x improvement in cycle life significantly reduces long-term replacement costs and operational disruptions.

Q: What charging time improvements can I expect with LiFePO4 technology?

A: LiFePO4 batteries accept much higher charging currents, enabling 2-4 hour charge times compared to 8-12 hours for lead-acid systems. This rapid charging capability particularly benefits fleet operations requiring quick turnaround times between shifts.

Q: Are there special considerations for cold weather operation?

A: LiFePO4 batteries perform better than lead-acid in cold conditions, maintaining capacity down to -20°C. However, charging should be avoided below 0°C unless the BMS includes heating elements. Our BMS technology includes thermal management features addressing these considerations.

Partner with TOPAK for Superior Low Speed EV LiFePO4 Battery Solutions

TOPAK's proven track record as a trusted Low Speed EV LiFePO4 Battery manufacturer spans over 15 years of innovation and excellence. Our comprehensive approach combines cutting-edge battery technology with unmatched technical support, ensuring your projects succeed from concept through deployment. Whether you're an OEM seeking customized solutions or a distributor requiring reliable supply chains, our team delivers results that exceed expectations. Ready to transform your electric vehicle applications with industry-leading battery technology? We invite you to contact us at B2B@topakpower.com to discuss your specific requirements.

References

1. Zhang, M., et al. "Thermal Stability and Safety Characteristics of LiFePO4 Batteries in Electric Vehicle Applications." Journal of Power Sources, 2023.

2. Anderson, J.K. "Comparative Analysis of Battery Management Systems in Low-Speed Electric Vehicles." Electric Vehicle Technology Review, 2023.

3. Chen, L., and Wang, S. "Cycle Life Performance of Lithium Iron Phosphate Batteries Under Various Operating Conditions." Battery Science International, 2022.

4. Thompson, R.D. "Economic Benefits of LiFePO4 Battery Adoption in Commercial Fleet Operations." Transportation Energy Economics, 2023.

5. Kumar, A., et al. "Environmental Impact Assessment of LiFePO4 vs Lead-Acid Batteries in Electric Mobility." Sustainable Energy Journal, 2023.

6. Williams, P.J. "Fast Charging Technologies for Low-Speed Electric Vehicle Applications." Electric Power Systems Research, 2022.