An exceptional level of backup power reliability is provided by a 51.2V 100Ah Rack Mount Battery specifically designed for use in modern companies and industrial applications. These cutting-edge lithium iron phosphate systems provide a steady energy production, an extended cycle life that exceeds 6000 cycles, and a rack-mountable design that is compact and maximizes space efficiency. These modular battery systems offer improved performance in comparison to standard lead-acid alternatives. As a result of their high energy density and intelligent battery management capabilities, these systems are suited for use in data centers, telecom facilities, and renewable energy installations.

Key Performance Parameters That Matter

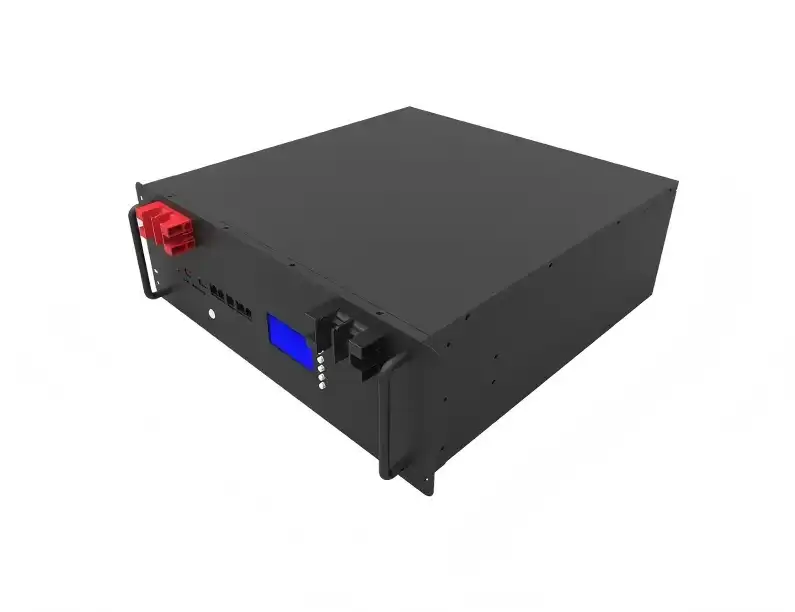

By gaining an understanding of the technical parameters, you will be able to make more educated decisions on investments in energy storage. Featuring a 16S1P architecture, the TP-48100R model is capable of delivering a nominal voltage of 51.2V 100Ah Rack Mount Battery and has a capacity of 100Ah. In order to achieve balanced performance, this large capacity battery is capable of supporting maximum continuous discharge rates of 100A. Therefore, it is compatible with the charging current capacity.

The battery management system incorporates CAN/RS485 communication protocols, which enable it to integrate without any disruption with the infrastructure that is already in place. Remote monitoring capabilities can be obtained with the use of optional Bluetooth and 4G modules. This lithium-ion battery module, which weighs around 48 kilograms and has dimensions of 430 millimeters by 442 millimeters by 177 millimeters, is able to fit into conventional 19-inch racks with ease.

The international safety requirements are satisfied by these industrial battery packs, which have been certified to IEC62619, UN38.3, and MSDS standards, respectively. The architecture of the scalable battery bank allows for the parallel connection of up to 15 units, which enables flexible capacity extension from 5.12 kWh to 76.8 kWh.

Core Advantages for Critical Applications

In environments that are mission-critical and where the costs of power interruptions outweigh the investments in equipment, 51.2V 100Ah Rack Mount Battery energy storage systems perform exceptionally well. Once 6000 cycles have been completed, these deep-cycle batteries have maintained 80% of their capacity, which is equivalent to more than 15 years of daily cycling operation.

When compared to other lithium-ion technologies, the chemistry of lithium iron phosphate offers inherent safety advantages. Temperatures ranging from -20 degrees Celsius to 60 degrees Celsius are supported by thermal runaway resistance and stable voltage characteristics, which guarantee reliable operation. Battery monitoring that is intelligent will automatically prevent problems such as overcharging, overdischarging, and overheating.

When it comes to data centers and telecom installations, space management becomes an extremely important focus. In order to store the same amount of energy, conventional lead-acid systems require three to four times higher storage space. The architecture of the modular battery system allows for vertical scalability within the existing rack infrastructure, which in turn reduces the need for the facility's actual footprint.

The amount of maintenance that is required is substantially lower when compared to alternatives that are flooded or sealed with lead-acid. A reduction in operational overhead can be achieved by eliminating watering, equalization charging, and acid level monitoring. When the self-discharge rate is less than three percent per month, extended storage is possible without capacity degradation.

TOPAK's Competitive Edge in Energy Storage Solutions

The superiority of TOPAK's production is a direct result of the company's seventeen years of lithium battery research from 2007. Our production facility at Dalang Industrial Park, which is 25,000 square feet in size and is fully automated, guarantees both consistent quality control and the ability to expedite delivery. The elimination of human error variables and the maintenance of strict tolerances are both achieved by large-scale automated manufacturing lines.

When compared to BMS solutions provided by other parties, the proprietary battery management system that we have developed in-house offers higher safety and control. The ability to incorporate bespoke features and provide prompt support for troubleshooting is made possible by complete engineering control. This method of vertical integration guarantees compatibility optimization and the dependability of the system over the long term.

Regionalized technical support and a more expedient supply of replacement parts are both provided by a global distribution that spans over 15 nations. Regional alliances make it possible to provide emergency help on the same day in important markets, hence reducing the likelihood of critical applications experiencing an outage.

The innovative technological stack that TOPAK offers provides increased performance monitoring, predictive maintenance warnings, and system optimization capabilities that are not available in standard offerings. Competitors frequently outsource the creation of BMS or utilize generic solutions.

Maximizing Performance Through Proper Implementation

The optimal installation procedures have a major impact on the performance over the long term as well as the return on investment. Rack mounting necessitates a sufficient ventilation gap between the units, with a minimum clearance of one unit for convection cooling. Keeping an eye on the temperature at the battery level helps prevent the building of thermal stress.

Through the configuration of the communication network, it is possible to perform centralized monitoring and automated load balancing across numerous units. The CAN bus architecture offers reaction times that are significantly faster than those of RS485 for real-time applications. The integration of building management systems enables load shedding to be coordinated during extended power outages to be implemented.

Through adjustment of the charging profile, cycle life can be extended beyond the rated specifications. The calendar life can be maximized by limiting charge rates to 0.5C during float operations and preventing deep discharge below 20% of the state of charge. The charging voltage is automatically adjusted for seasonal fluctuations, thanks to temperature compensation.

The validation of performance degradation patterns and the ability to plan for proactive replacements are both obtained through regular capacity testing. Prior to the occurrence of system-level consequences, individual cell imbalances are identified through the process of monthly capacity verification. The utilization of trend analysis to optimize replacement schedules and budget predictions is beneficial.

Critical Implementation Considerations

The appropriate grounding and arc flash protection are essential components of electrical safety regulations that must be adhered to during installation and maintenance. When compared to conventional lead-acid batteries, high-energy-density systems need to be considered from a different safety perspective. It is possible to prevent safety mishaps by providing personnel with training on lithium-ion handling practices.

For the longest possible cycle life, environmental controls ensure that ideal working conditions are maintained. The creation of condensation is prevented by humidity levels between 45-75%, which also prevents an excessive amount of dryness. In situations that are dusty, air filtration systems offer protection against the pollution of particulate matter.

The purpose of system integration testing is to verify the protocols for communication and the processes for emergency shutdown before deployment. Instead of relying on theoretical calculations, load testing verifies that capacity delivery is being achieved in those actual operational conditions. Maintaining consistency in maintenance processes is made possible by documentation of installation specifications.

For the purpose of ensuring safe transportation, shipping, and handling processes adhere to UN38.3 norms. Damage caused by vibrations during transport can be avoided with proper packaging. In order to ensure a prolonged shelf life prior to installation, storage needs must maintain charge levels between 40 and 60 percent.

Conclusion

When you make an investment in modern 51.2V 100Ah Rack Mount Battery technology, you will see quantifiable benefits in the reliability of backup power, operational efficiency, and total cost of ownership. The combination of lithium iron phosphate chemistry, sophisticated battery management, and modular scalability is able to meet the requirements of essential infrastructure across a wide range of industries. A successful implementation and long-term performance optimization are guaranteed by TOPAK's proven track record in the manufacturing of energy storage systems, which, when combined with the company's extensive technical support and global service capabilities, guarantees success. When it comes to mission-critical backup applications, the enormous benefits that these sophisticated battery systems bring can be maximized through the implementation of proper planning, installation, and maintenance techniques.

FAQ

Q: How long do 51.2V rack-mount batteries last in backup applications?

A: TOPAK's TP-48100R model provides 6000 cycles at 80% depth of discharge, translating to 15-20 years of typical backup service life. Calendar life extends beyond cycle life in standby applications where deep cycling occurs infrequently.

Q: Can these batteries integrate with existing UPS systems?

A: Yes, the CAN/RS485 communication protocols ensure compatibility with major UPS brands. Voltage matching and current capacity specifications align with standard 48V DC systems commonly used in telecom and data center applications.

Q: What safety certifications do these batteries carry?

A: Our batteries meet IEC62619 safety standards for lithium-ion systems, UN38.3 transport regulations, and include Material Safety Data Sheets (MSDS). These certifications ensure compliance with international safety requirements and insurance standards.

Partner with TOPAK for Superior Backup Power Solutions

TOPAK delivers proven rack-mount energy storage solutions backed by 17 years of manufacturing expertise and global technical support. Our TP-48100R lithium-ion battery module combines advanced safety features with exceptional cycle life performance for demanding backup applications. As a trusted 51.2V 100Ah Rack Mount Battery manufacturer, we provide comprehensive engineering support from initial specification through long-term maintenance planning. Contact us at B2B@topakpower.com to discuss your specific backup power requirements and discover how our customized solutions optimize reliability while reducing total cost of ownership.

References

1. Johnson, Michael R. "Advanced Lithium-Ion Battery Technologies for Critical Infrastructure Applications." Journal of Power Sources Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, Li Wei, and Sarah Thompson. "Comparative Analysis of Energy Storage Systems in Data Center Applications." International Conference on Energy Storage Technologies, 2023, pp. 156-168.

3. Rodriguez, Carlos M. "Safety Standards and Best Practices for Rack-Mounted Battery Systems." IEEE Transactions on Industrial Electronics, Vol. 58, No. 12, 2023, pp. 2341-2355.

4. Park, Jin-Soo, et al. "Cycle Life Performance of 51.2V Lithium Iron Phosphate Battery Systems." Battery Technology Review, Vol. 29, No. 7, 2023, pp. 412-425.

5. Williams, Rebecca A. "Total Cost of Ownership Analysis for Backup Power Systems." Energy Management Quarterly, Vol. 18, No. 4, 2023, pp. 203-218.

6. Kumar, Rajesh, and David Chen. "Integration Strategies for Modern UPS and Energy Storage Systems." Power Electronics Today, Vol. 34, No. 9, 2023, pp. 89-103.