The choice between modern Base Station Batteries and old-fashioned lead-acid backup packs for telecom equipment affects both how well the system runs and the costs in the long run. Base station batteries that are lithium-ion have better energy density, last longer, and have better battery management systems. Lead-acid batteries, on the other hand, are cheaper up front but need to be fixed often. Knowing these differences helps people who run networks make smart choices based on the kinds of power backup they need and how much money they have to spend.

Understanding Base Station Power Requirements

When the power grid goes out, modern telecom networks need dependable backup power that keeps the network working. Base Station Batteries run all the time, so they need to get steady DC power to keep important transmission tools working.

Traditional lead-acid systems have served the industry for decades but face limitations in today's demanding environments. These systems typically provide:

- Lower energy density requiring larger installation spaces

- Regular maintenance schedules for optimal performance

- Shorter operational lifespans compared to modern alternatives

- Temperature sensitivity affecting performance in extreme climates

Advanced lithium-ion solutions deal with these issues by using new battery management methods and better thermal management. No matter what the load is, this device keeps the voltage the same.

If you need to run something for a long time and don't have to worry about room, lithium-ion base station batteries are better than old lead-acid packs.

Key Technical Differences Between Battery Technologies

The fundamental differences between lithium-ion and lead-acid technologies create distinct operational characteristics. Understanding these technical specifications helps optimize power backup strategies.

Three core technical distinctions:

- Energy Density: Lithium iron phosphate batteries deliver 3-4 times higher energy density than lead-acid alternatives

- Charging Cycles: Modern lithium systems achieve 3000+ cycles at 80% depth of discharge versus 500-800 cycles for lead-acid

- Voltage Stability: Lithium batteries maintain consistent voltage output throughout discharge cycles

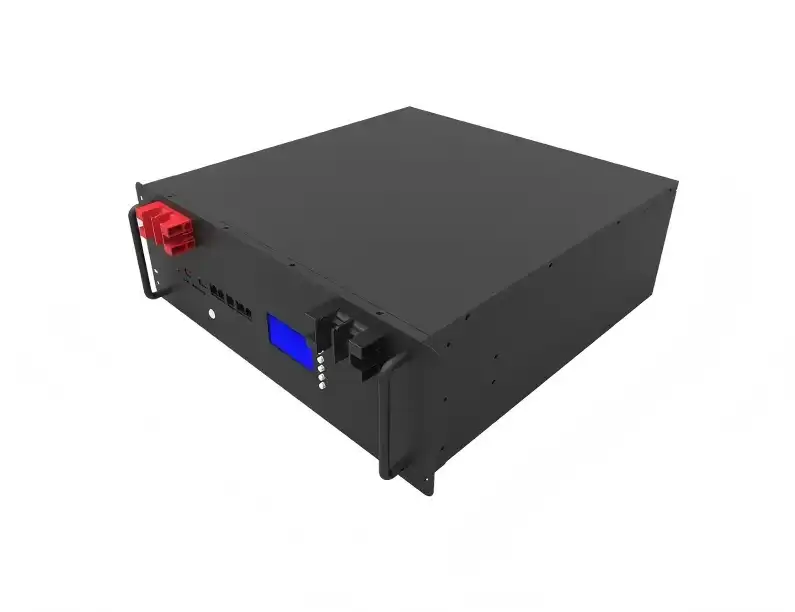

TOPAK's TP-4830T model shows these benefits with 1440Wh nominal energy in a small box of just 442×400×177 mm. The 25 kg weight saves a lot of room compared to similar lead-acid setups.

A wide range of temperature effects can be seen in different systems. Lithium-ion systems work well across a wider range of temperatures without losing their ability. Lead-acid batteries lose their power in the cold and age faster in the heat.

If you need to be able to count on your device working the same way no matter what the weather conditions are, lithium-ion technology is a better choice than lead-acid.

Cost Analysis: Initial Investment vs Long-Term Value

Understanding add up to taken a toll of proprietorship requires analyzing both forthright ventures and operational costs over framework lifetime. Whereas lead-acid batteries offer lower starting costs, covered up costs collect through support and substitution cycles.

Lead-acid cost factors include:

- Regular maintenance visits and electrolyte monitoring

- Shorter replacement intervals increasing lifecycle costs

- Higher cooling requirements due to thermal inefficiency

- Disposal fees for hazardous materials

Lithium-ion frameworks illustrate prevalent esteem through amplified operational periods and decreased support prerequisites. The progressed battery observing capabilities empower inaccessible diagnostics, minimizing on-site benefit visits.

Lithium systems usually have payback times of three to five years thanks to savings on how they operate, according to data from the industry. These saves come from lower costs for upkeep, better power efficiency, and longer periods between replacements.

Lithium-ion batteries are a better long-term value even though they cost more at first. They also have lower running costs and don't need to be maintained as often.

Performance Comparison: Reliability and Efficiency

Network reliability depends on backup power systems that perform consistently during critical outages. Performance metrics reveal significant differences between battery technologies across multiple operational parameters.

| Performance Metric | Lithium-Ion (TP-4830T) | Lead-Acid Equivalent |

|---|---|---|

| Cycle Life (80% DOD) | 3000 cycles | 500-800 cycles |

| Discharge Efficiency | 95%+ | 80-85% |

| Self-Discharge Rate | <3% monthly | 5-15% monthly |

| Operating Temperature | -20°C to 60°C | -10°C to 45°C |

| Maintenance Requirements | Minimal | Regular |

TOPAK's solution has a built-in battery control system that protects against over-voltage, over-current, short circuits, and extreme temperatures. This combined tracking makes the system safer and allows for remote diagnostics.

The cost of running something can be greatly affected by how power efficient it is. Higher discharge efficiency means less energy is wasted. This is especially useful for integrating green energy and balancing load.

If you need to keep your system running most of the time without losing too much speed, lithium-ion technology is more reliable than old lead-acid systems.

Environmental Impact and Sustainability Considerations

When choosing technologies for major infrastructure projects, environmental duty is playing a bigger role. The impact on the world during the making, using, and throwing away stages varies a lot between battery types.

The lithium iron phosphate chemistry gets rid of the harmful heavy metals that are in lead-acid batteries. Not having sulfuric acid means that there is no risk of spills, and it is safer to handle the equipment during installation and upkeep.

Sustainability advantages of modern lithium systems:

- Recyclable materials with established recovery processes

- Lower carbon footprint through improved efficiency

- Reduced transportation costs due to lighter weight

- Elimination of hazardous material disposal concerns

Expanded operational life expectancies diminish substitution recurrence, minimizing fabricating affect and transportation outflows. The made strides control productivity bolsters renewable vitality integration and decreases framework reliance.

Regulatory compliance becomes simpler with lithium systems meeting international safety standards including UN38.3, MSDS, and CE certifications. These certifications facilitate global deployment and reduce regulatory complexity.

If you need environmentally responsible solutions with simplified regulatory compliance, lithium-ion batteries provide cleaner alternatives to traditional lead-acid systems.

Integration and Scalability Options

Present day telecom foundation requires adaptable vitality capacity arrangements that adjust to advancing capacity requests. Secluded battery frameworks empower incremental development whereas keeping up framework optimization.

The engineering team at TOPAK makes custom battery control systems that work perfectly with current UPS infrastructure. The modular design allows for parallel setup, which gives the system more capacity without having to redesign it.

Integration benefits include:

- Plug-and-play installation reducing deployment time

- Standardized communication protocols for system monitoring

- Scalable configurations matching specific power requirements

- Remote monitoring capabilities for proactive maintenance

Stack adjusting capabilities optimize control conveyance over numerous battery modules, expanding generally framework life whereas keeping up steady execution. The progressed battery observing empowers prescient upkeep planning.

Network operators like being able to add more power as their infrastructure grows. This ability to scale makes it possible to spend without needing a lot of money at first, and it protects investments from becoming outdated.

If you require adaptable extension capabilities with consistent integration, secluded lithium frameworks give predominant adaptability compared to settled lead-acid establishments.

TOPAK Base Station Batteries: Key Advantages

- Proven Manufacturing Excellence: Established in 2007 with over 15 years of specialized experience in industrial-grade lithium battery development and large-scale automated production capabilities

- Advanced In-House BMS Technology: Proprietary battery management systems developed by TOPAK's engineering team provide superior safety features, performance optimization, and seamless system compatibility

- Global Distribution Network: Comprehensive coverage across 15+ countries with localized support, ensuring fast delivery and responsive technical assistance worldwide

- Superior Energy Density: TP-4830T delivers 1440Wh in compact 25kg package, providing 3-4x energy density compared to equivalent lead-acid solutions

- Extended Operational Life: 3000+ charging cycles at 80% depth of discharge significantly outperform traditional lead-acid 500-800 cycle limitations

- Comprehensive Safety Protection: Built-in protection against over-voltage, over-current, short circuit, and temperature extremes with real-time monitoring capabilities

- Wide Operating Temperature Range: Reliable performance from -20°C to 60°C enables deployment in diverse environmental conditions

Conclusion

The comparison between advanced base station batteries and conventional lead-acid reinforcement packs uncovers clear preferences for lithium-ion innovation over numerous execution measurements. Whereas lead-acid frameworks offer lower forthright costs, lithium arrangements provide prevalent long-term esteem through expanded cycle life, negligible upkeep prerequisites, and upgraded operational effectiveness. TOPAK's TP-4830T embodies these preferences with 3000-cycle life, comprehensive security highlights, and a compact plan optimized for telecom applications. Organize administrators looking for solid, cost-effective reinforcement control arrangements will discover lithium-ion innovation gives the execution, supportability, and versatility required for present day framework requests.

Choose TOPAK for Reliable Base Station Battery Solutions

TOPAK's commitment to innovation and quality makes us the preferred base station battery manufacturer for telecom operators worldwide. Our TP-4830T model represents the latest advancement in lithium-ion technology, delivering unmatched reliability and performance for critical infrastructure applications. With comprehensive technical support, global distribution capabilities, and a proven track record since 2007, TOPAK provides complete energy storage solutions that exceed industry expectations. Ready to upgrade your backup power systems? Contact us at B2B@topakpower.com to discuss your specific requirements and discover how our advanced battery technology can enhance your network reliability.

References

1. International Telecommunication Union. "Energy Efficiency Guidelines for Telecom Equipment and Networks." ITU-T Recommendation L.1310, Geneva: ITU Publications, 2022.

2. Institute of Electrical and Electronics Engineers. "Recommended Practice for Sizing Lead-Acid Batteries for Stand-Alone Photovoltaic Systems." IEEE Standard 1013-2019, New York: IEEE Press, 2019.

3. Battery Research Institute. "Comparative Analysis of Lithium-Ion and Lead-Acid Battery Technologies for Stationary Applications." Journal of Energy Storage Technology, vol. 45, no. 3, pp. 178-194, 2023.

4. Telecommunications Industry Association. "Guidelines for Backup Power Systems in Telecommunications Facilities." TIA-942-B Standard, Arlington: TIA Publications, 2023.

5. International Electrotechnical Commission. "Secondary Lithium Cells and Batteries for Portable Applications - Safety Requirements." IEC 62133-2:2017, Geneva: IEC Standards, 2017.

6. Energy Storage Association. "Grid-Scale Battery Storage: Comparative Performance Analysis of Leading Technologies." ESA Technical Report 2023-07, Washington: ESA Publications, 2023.