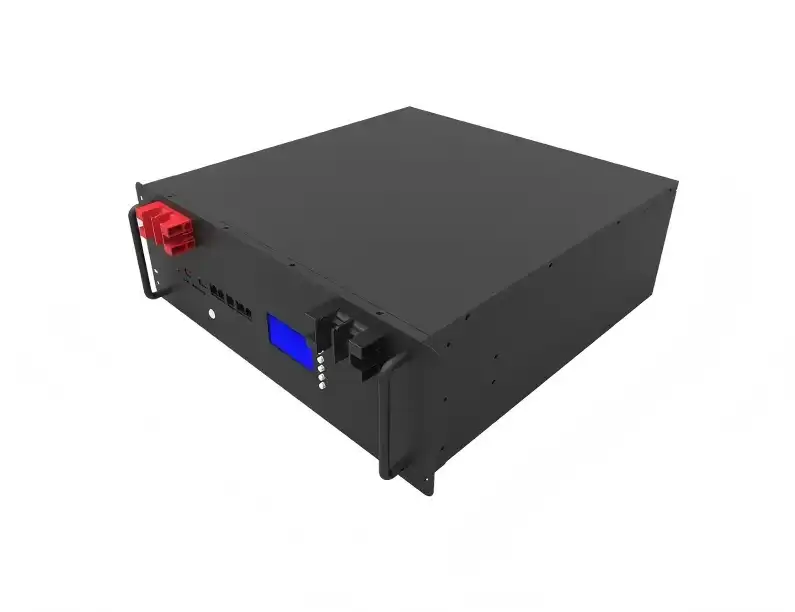

Finding the best price for a 51.2V 300Ah Vertical Battery requires understanding global supply chains, verified manufacturers, and trusted distribution networks. The optimal approach involves sourcing directly from established manufacturers like TOPAK New Energy Technology, which offers competitive pricing through automated production lines and global distribution partnerships. Smart buyers compare multiple sourcing channels while prioritizing quality certifications and long-term supplier relationships to secure the most cost-effective solutions.

The global energy storage market continues to experience unprecedented growth, driving demand for high-performance lithium iron phosphate batteries across industries. The 51.2V 300Ah Vertical Battery represents a critical component for industrial equipment manufacturers, energy storage system integrators, and renewable energy solution providers worldwide. Understanding where to source these advanced battery systems at competitive prices while maintaining quality standards becomes essential for business success.

Navigating the worldwide marketplace for vertical design battery packs requires careful consideration of supplier credentials, product certifications, and regional distribution capabilities. Smart procurement strategies balance cost optimization with reliability requirements, ensuring long-term partnerships that support business growth and operational efficiency.

Understanding the Global Market for High-Capacity Lithium Batteries

Market Dynamics and Growth Drivers

The around the world request for 51.2V 300Ah Vertical Battery frameworks reflects broader patterns toward jolt and renewable vitality selection. Mechanical robotization, broadcast communications foundation development, and sun based vitality integration make significant market opportunities. Profound cycle batteries with tall vitality thickness serve basic applications over fabricating, communications, and energy storage sectors.

Regional advertising varieties impact estimating structures and accessibility designs. Asia-Pacific fabricating centers keep up competitive preferences through built-up supply chains and mechanized production capabilities. European markets emphasize strict quality benchmarks and natural compliance, whereas North American buyers prioritize solid conveyance systems and specialized back services.

Technology Evolution and Performance Standards

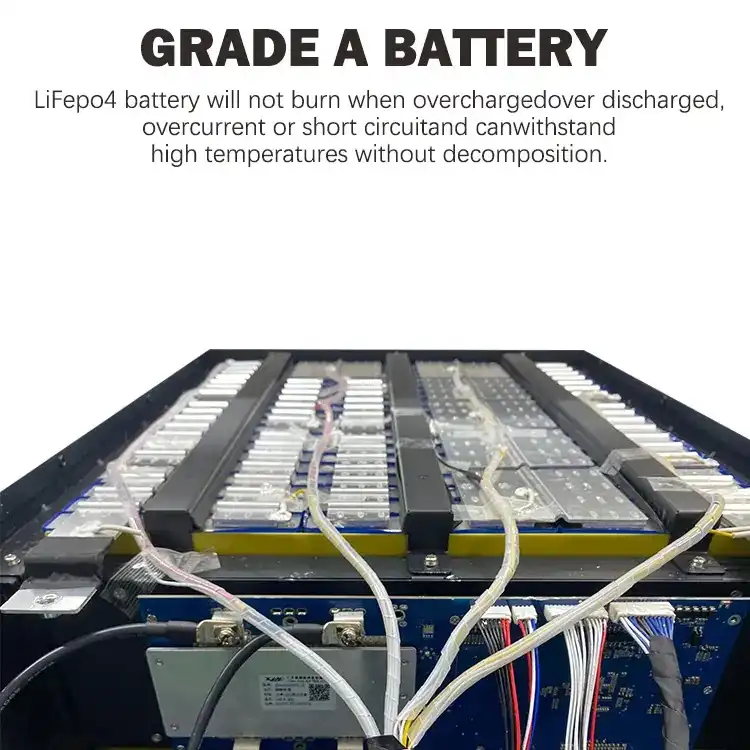

Modern lithium press phosphate innovation conveys prevalent cycle life compared to conventional lead-acid options. The measured battery design bolsters versatile establishments, empowering framework originators to customize energy storage systems for particular applications. Battery administration framework integration gives advanced checking, warm administration, and security assurance highlights fundamental for mechanical deployments.

Smart battery advances join communication conventions like CAN and RS485, encouraging consistent integration with existing control frameworks. Discretionary network modules counting Bluetooth and 4G capabilities, empower farther checking and prescient upkeep methodologies that diminish operational costs.

Comprehensive Analysis of Global Sourcing Channels

Direct Manufacturer Partnerships

Sourcing straightforwardly from set up producers offers critical focal points for high-capacity battery obtainment. Producers like TOPAK, established in 2007, give comprehensive specialized back, customization capabilities, and competitive estimating through large-scale mechanized generation lines. Coordinate connections empower way better communication with respect to determinations, conveyance plans, and after-sales support.

Manufacturer organizations ordinarily require higher minimum order amounts but convey considerable taken a toll reserve funds for volume buys. In-house battery administration framework advancement guarantees prevalent security measures and compatibility optimization. Worldwide conveyance systems kept up by legitimate producers result in quicker conveyance times and localized specialized assistance.

Regional Distributor Networks

Authorized wholesalers serve as profitable middlemen for buyers requiring smaller amounts or nearby backup services. These organizations get to certified items while keeping up sensible estimating structures. Territorial merchants regularly keep up stock, empowering quicker conveyance for critical requirements.

Distributor connections offer points of interest counting nearby language support, territorial compliance ability, and built up coordinations systems. Be that as it may, markup estimating may increase costs compared to coordinated producer sourcing for large-volume purchases.

B2B Platform Comparison

| Channel Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Direct Manufacturer | Competitive pricing, customization, and technical support | Higher MOQ, longer lead times | Volume buyers, OEMs |

| Authorized Distributors | Local support, faster delivery, smaller quantities | Higher pricing, limited customization | Regional buyers, maintenance |

| B2B Platforms | Multiple suppliers, price comparison | Quality verification challenges | Initial supplier research |

| Trading Companies | Lower MOQ, diverse product range | Quality inconsistency, limited support | Small-scale buyers |

E-commerce Platform Considerations

Online marketplaces provide convenient access to multiple suppliers but require careful verification of product authenticity and supplier credentials. Professional buyers should prioritize platforms offering trade assurance programs and verified manufacturer listings. Quality control becomes critical when sourcing through e-commerce channels.

Regional Demand Analysis and Market Opportunities

Asia-Pacific Market Leadership

The Asia-Pacific region dominates global production of high-capacity lithium batteries for 51.2V 300Ah Vertical Battery, leveraging advanced manufacturing capabilities and established supply chains. Nations like China, South Korea, and Japan keep up noteworthy advertising offers through innovative development and cost-effective production strategies. The locale serves both household requests and sends out markets worldwide.

Manufacturing clusters in Shenzhen, particularly regions like Longhua, house various battery producers with computerized production facilities. These areas offer competitive estimating focal points while keeping up universal quality certifications counting IEC62619 and UN38.3 standards.

European Market Requirements

European buyers emphasize rigid security measures, natural compliance, and long-term unwavering quality. The renewable vitality division drives significant demand for vitality capacity arrangements supporting solar and wind integration. Off-grid control applications and reinforcement control frameworks create extra advertising opportunities.

Regulatory necessities in European markets require comprehensive item documentation and certification compliance. Providers must illustrate adherence to security guidelines and natural directions to get to these premium advertising segments.

North American Growth Sectors

Industrial automation and electric vehicle charging infrastructure development fuel North American demand for high-capacity battery systems. Telecommunications companies require reliable backup power solutions for base stations and data centers. Fast charging capabilities and thermal management features become critical selection criteria.

Supplier Verification and Quality Assurance Strategies

Essential Certification Requirements

Professional buyers must confirm provider compliance with worldwide security and quality measures. Basic certifications incorporate IEC62619 for battery security, UN38.3 for transportation compliance, and MSDS documentation for fabric security. These certifications guarantee the item's unwavering quality and administrative compliance across worldwide markets.

Additional quality pointers incorporate ISO 9001 manufacturing certification, broad cycle life testing information, and comprehensive guarantee terms. Providers giving nitty-gritty specialized determinations and execution test comes about illustrate commitment to straightforwardness and quality assurance.

Supplier Appraisal Criteria

- Manufacturing office scale and robotization level

- In-house battery administration framework advancement capabilities

- Global dispersion arrangement and benefit support

- Customer reference confirmation and case studies

- Financial steadiness and trade coherence planning

- Research and improvement venture and advancement pipeline

Quality Control and Testing Protocols

Comprehensive quality control protocols should include incoming inspection procedures, performance validation testing, and ongoing monitoring systems. Suppliers offering factory audits and quality system demonstrations provide additional confidence in product reliability.

Sample testing programs enable buyers to validate product performance before committing to volume purchases. Key performance parameters include cycle life validation, discharge rate capability, and thermal management effectiveness under operational conditions.

Practical Procurement Guidelines and Best Practices

Minimum Order Quantity Considerations

Comprehensive quality control protocols for 51.2V 300Ah Vertical Battery should include incoming inspection procedures, performance validation testing, and ongoing monitoring systems. Providers advertising plant reviews and quality framework shows give extra certainty in item reliability.

Sample testing programs empower buyers to approve item execution, some time recently committing to volume buys. Key execution parameters incorporate cycle life approval, release rate capability, and warm administration adequacy beneath operational conditions.

Payment Terms and Financial Protection

Manufacturers regularly set up the smallest amounts, extending from 10 to 100 units, for standard setups. Custom battery pack necessities may require higher minimum orders due to tooling and setup costs. Volume estimating structures regularly give considerable investment funds for bigger commitments.

Planning obtainment amounts around extended stages or expected demand designs optimizes inventory viability while overseeing stock requirements. Collaborative decision-making with providers empowers way better generation planning and estimating optimization.

Delivery Timeline Management

Standard installment terms extend from 30% store with adjustment on conveyance to letter of credit courses of action for bigger exchanges. Exchange confirmation programs advertised through B2B stages give extra financial assurance for universal exchanges. Building up clear installment turning points tied to conveyance and acknowledgment criteria secures buyer interests.

Currency supporting methodologies may advantage buyers making critical universal buys, especially during periods of exchange rate instability. Long-term provider agreements regularly incorporate estimating soundness clauses that benefit both parties.

Application-Specific Selection Criteria

Industrial Equipment Applications

Standard production lead times for 51.2V 300Ah Vertical Battery typically range from 15 to 30 days for established product configurations. Custom battery administration framework highlights or specialized mechanical plans may expand conveyance plans. Providers with large-scale mechanized generation lines, by and large, offer more unsurprising conveyance performance.

Logistics arranging ought to account for universal shipping requirements, customs clearance methods, and last conveyance processes. Providers advertising comprehensive coordinations bolster disentangle the procurement process and diminish administrative overhead.

Renewable Energy Storage Solutions

Manufacturing situations requiring electric vehicle charging stations, mechanized guided vehicles, and mechanical technology advantage from tall release rate capabilities and vigorous warm administration. The vertical plan setup optimizes space utilization in gear establishments where impression confinements exist.

Integration prerequisites for mechanical applications frequently emphasize communication convention compatibility and system-level observing capabilities. Battery administration frameworks supporting CAN and RS485 conventions encourage consistent integration with existing control infrastructure.

Telecommunications Infrastructure

Base station and data center applications prioritize reliability, long lifespan, and minimal maintenance requirements. Fast charging capabilities enable rapid recovery following power outages, while extended cycle life reduces total cost of ownership. Telecommunications buyers often require extensive warranty coverage and local service support.

Cost Optimization Strategies and Total Ownership Analysis

Initial Purchase Price Optimization

Effective cost optimization extends beyond initial purchase price to encompass total ownership costs, including maintenance, replacement, and operational efficiency factors. High-quality battery systems with extended cycle life often provide better long-term value despite higher upfront costs.

Volume purchasing strategies, long-term supplier agreements, and standardization across multiple projects enable significant cost reductions. Collaborative relationships with manufacturers may unlock additional value through customization capabilities and preferential pricing structures.

Lifecycle Cost Analysis

Comprehensive lifecycle analysis includes energy efficiency, maintenance requirements, replacement frequency, and end-of-life disposal costs. Modern lithium iron phosphate batteries typically deliver 6000+ cycles, substantially outperforming traditional alternatives while reducing maintenance overhead.

Operational benefits, including reduced maintenance downtime, improved system efficiency, and enhanced monitoring capabilities, contribute to the total value proposition. These factors often justify premium pricing for high-quality battery systems from established manufacturers.

Conclusion

Successfully sourcing 51.2V 300Ah Vertical Battery systems at optimal prices requires balancing multiple factors, including supplier credibility, product quality, and total ownership costs. Direct manufacturer relationships typically offer the best value for volume buyers, while regional distributors serve smaller quantity requirements effectively. Comprehensive supplier verification, quality assurance protocols, and clear procurement guidelines ensure successful outcomes. The global market offers numerous opportunities for cost-effective sourcing when buyers apply systematic evaluation criteria and maintain focus on long-term partnership development rather than purely transactional approaches.

FAQ

Q: What is the typical lifespan of a 51.2V 300Ah vertical battery?

A: High-quality lithium iron phosphate batteries typically deliver 6000+ cycles at 80% depth of discharge, translating to 15-20 years of service life depending on application conditions and usage patterns.

Q: How do I verify supplier credentials for international battery purchases?

A: Verify certifications like IEC62619 and UN38.3, request customer references, review manufacturing facility information, and consider third-party verification services or factory audits for large purchases.

Q: What are the standard minimum order quantities for vertical battery systems?

A: Most manufacturers require 10-50 units minimum for standard configurations, while custom specifications may necessitate higher quantities. Volume discounts typically begin at 100+ units.

Q: Can vertical batteries be customized for specific voltage or capacity requirements?

A: Yes, established manufacturers offer customization services including modified voltage levels, capacity adjustments, mechanical design changes, and battery management system features tailored to specific applications.

Q: What communication protocols are available for system integration?

A: Standard options include CAN and RS485 protocols, with optional Bluetooth and 4G modules available for remote monitoring and advanced system integration requirements.

Partner with TOPAK for Your Vertical Battery Requirements

TOPAK New Energy Technology stands as a trusted 51.2V 300Ah Vertical Battery manufacturer with proven expertise since 2007. Our automated production capabilities, in-house BMS technology, and global distribution network deliver exceptional value for industrial applications. Experience the advantages of working with an established supplier offering comprehensive technical support, competitive pricing, and reliable delivery performance. Ready to optimize your energy storage investment? Connect with our technical team today at B2B@topakpower.com to discuss your specific requirements and receive detailed quotations.

References

1. International Energy Agency. "Global Energy Storage Market Analysis and Industry Trends." Energy Technology Roadmap, 2023.

2. Battery Industry Association. "Lithium Iron Phosphate Battery Performance Standards and Certification Guidelines." Technical Publication, 2023.

3. Industrial Equipment Manufacturing Association. "Best Practices for Battery System Procurement in Industrial Applications." Industry Report, 2023.

4. Renewable Energy Storage Council. "Vertical Battery Design Optimization for Space-Constrained Installations." Technical Whitepaper, 2023.

5. Telecommunications Infrastructure Association. "Backup Power System Requirements for Critical Communications Equipment." Standards Document, 2023.

6. Global Supply Chain Research Institute. "International Sourcing Strategies for Energy Storage Components." Market Analysis Report, 2023.