When looking for a solid wall mounted battery provider, confirmation becomes vital for effective acquisition. Basic checkpoints incorporate producer certifications (IEC62619, UN38.3), generation capacity appraisal, quality control frameworks assessment, and specialized support capabilities. Furthermore, confirm the supplier's involvement with customized battery arrangements, worldwide dispersion arrange, and post-sales service quality. These confirmation steps guarantee you are associated with a producer competent of conveying high-performance divider-mounted battery frameworks that meet your particular mechanical prerequisites and security standards.

China overwhelms the worldwide battery market, creating over 70% of the world's lithium batteries. The country's advanced fabricating framework, competitive pricing, and mechanical advancement make it an alluring goal for sourcing divider-mounted battery arrangements. In any case, exploring the endless provider scene requires cautious assessment and vital decision-making.

The divider-mounted battery showcase has experienced momentous development, driven by expanding demand for renewable energy capacity, mechanical robotization, and reinforcement control frameworks. Chinese producers have reacted with advanced generation capabilities, advertising everything from standard battery packs to completely customized energy storage solutions.

Understanding how to recognize dependable producers becomes fundamental for businesses looking for long-term associations. The right provider can give not only cost-effective arrangements but also specialized ability, quality assurance, and progress that drives trade success.

China's Manufacturing Excellence in Wall Mounted Battery Production

Advanced Production Infrastructure

Chinese divider-mounted battery producers work in state-of-the-art offices prepared with computerized production lines. These progressive frameworks guarantee reliable quality control, diminished manufacturing costs, and speedier delivery times. Numerous driving producers have contributed intensely to mechanical technology and developed insights to optimize their production processes.

The integration of computerized testing gear permits comprehensive quality checks at each generation stage. This efficient approach minimizes surrenders and guarantees that each divider-mounted battery unit meets rigid execution guidelines some time recently shipment.

Research and Development Capabilities

Innovation drives the Chinese battery industry forward. Driving producers keep up devoted R&D centers centered on creating next-generation battery innovations. These offices work persistently on making strides in vitality thickness, amplifying cycle life, and improving security features.

Many producers create restrictive Battery Administration Frameworks (BMS) in-house, giving total control over security features, execution optimization, and framework compatibility. This vertical integration approach guarantees way better quality control and speedier development cycles.

Supply Chain Integration

China's total lithium battery supply chain gives producers with get to to crude materials, components, and specialized hardware. This integration comes about in shorter lead times, with better control, and moves forward supply chain resilience.

The nearness to component providers empowers producers to actualize just-in-time production procedures, decreasing inventory costs while keeping up production flexibility. This advantage translates into competitive estimating for universal customers.

Strategic Approaches to Identifying Reliable Wall Mounted Battery Manufacturers

Manufacturing Experience and Track Record

Evaluate producers based on their industry experience and demonstrated track record. Companies set up for over a decade regularly have more profound specialized skills and steadier operations. See for producers who have effectively served comparative businesses and applications.

Review case thinks about, client tributes, and extend portfolios to evaluate the manufacturer's capability in conveying complex wall mounted battery arrangements. Experienced producers can give profitable experiences into the framework plan and application optimization.

Production Capacity Assessment

Assess the manufacturer's generation capacity to guarantee they can meet your volume necessities. Large-scale robotized generation lines show the capacity to handle significant orders while keeping up reliable quality standards.

Consider both current capacity and extension plans. Producers with versatile generation capabilities can develop with your trade needs, giving long-term supply security and organizational stability.

Technical Support and Engineering Services

Evaluate the manufacturer's specialized back capabilities, counting BMS customization, framework integration help, and application designing services. Solid specialized support guarantees effective item execution and progressing operational success.

Look for producers advertising comprehensive documentation, preparing programs, and providing nearby specialized support. These administrations essentially decrease usage dangers and quicken venture timelines.

Quality Management Systems

Examine the manufacturer's quality administration frameworks and continuous change forms. ISO 9001 certification shows commitment to quality, brilliance, and orderly improvement.

Review their testing strategies, quality control checkpoints, and disappointment investigation capabilities. Vigorous quality frameworks minimize item failures and guarantee dependable divider-mounted battery execution in demanding applications.

Global Distribution Network

Consider producers with set up worldwide conveyance systems and local supply capabilities. This foundation guarantees quicker conveyance, local specialized support, and simpler guarantee service.

Manufacturers serving 15+ nations illustrate their capacity to adjust items to distinctive market requirements and administrative benchmarks. This worldwide encounter translates into superior item planning and benefit capabilities.

Financial Stability and Business Reputation

Assess the manufacturer's budgetary stability through trade enrollment confirmation, budgetary reports audit, and credit evaluations. Steady producers give superior long-term association security and venture protection.

Research the company's notoriety through industry affiliations, exchange distributions, and client criticism. A solid notoriety shows reliable execution and moral trade practices.

Innovation and Future Development

Evaluate the manufacturer's commitment to development and innovation improvement. Companies contributing to R&D ordinarily offer more advanced items and superior long-term competitiveness.

Review their item guide and innovation associations to get their key heading. Forward-thinking producers can get to developing innovations and future-ready solutions.

Essential Certifications for Wall Mounted Battery Systems

International Safety Standards

IEC62619 certification guarantees that lithium battery frameworks meet universal security requirements for mechanical applications. This certification covers security testing, warm steadiness, and manhandle testing conventions fundamental for wall mounted battery applications.

UN38.3 certification approves the battery's security amid transportation, covering elevation recreation, warm testing, vibration, shock, and outside brief circuit tests. This certification is required for worldwide shipping.

Quality Management Certifications

ISO 9001 certification illustrates the manufacturer's commitment to quality administration frameworks and continuous change forms. This standard guarantees reliable item quality and solid fabrication processes.

Additional certifications like ISO 14001 (Natural Administration) and ISO 45001 (Word related Wellbeing and Security) show comprehensive management framework usage and corporate responsibility.

Regional Market Compliance

CE checking is required for divider-mounted battery deals in European markets, illustrating compliance with safety, security, and environmental protection measures. This certification empowers advertisers to access the European Union.

RoHS compliance guarantees that battery frameworks meet restrictions on hazardous substances, making them reasonable for ecologically cognizant markets and applications.

Application-Specific Certifications

UL certification may be required for certain North American markets, especially for private and commercial vitality capacity applications. This certification includes validity and advertised acceptance.

FCC certification for communication modules guarantees compatibility with remote communication measures, fundamental for keen battery administration and monitoring systems.

Effective Sourcing Channels and Platform Navigation

Industry Trade Shows and Exhibitions

Major vitality capacity presentations give openings to meet producers straightforwardly, look at item tests, and assess specialized capabilities. Occasions like Intersolar, Vitality Capacity Universal, and Battery Appear offer concentrated get to to driving suppliers.

Trade appears empower face-to-face dialogs, relationship building, and comprehensive item shows. These insights give profitable experiences into producer capabilities and corporate culture.

Professional B2B Platforms

Established B2B stages offer organized provider data, confirmation services, and exchange security. These stages give starting screening capabilities and fundamental provider appraisal tools.

Many stages offer provider confirmation services, counting trade permit approval, manufacturing plant review reports, and client input frameworks. These administrations offer assistance to diminish the starting assessment workload.

Industry Associations and Networks

Industry affiliations give access to confirmed partner companies and proficient organizing opportunities. Affiliation participation frequently shows commitment to industry measures and moral commerce practices.

Professional systems empower peer suggestions and involvement sharing, giving valuable experiences into provider execution and unwavering quality from industry colleagues.

Direct Manufacturer Contact

Contacting producers specifically through their official websites frequently gives the most comprehensive data and coordinate get to to specialized groups. This approach empowers nitty-gritty talks about particular necessities and capabilities.

Direct contact encourages way better communication, speedier reaction times, and more personalized benefits. It also empowers coordinate assessment of the manufacturer's communication capabilities and specialized expertise.

Optimizing OEM and ODM Collaboration Strategies

Technical Specification Development

Clearly define technical requirements, including voltage specifications, capacity requirements, physical dimensions, and environmental operating conditions. Detailed specifications ensure accurate quotations and proper product design.

Include communication protocol requirements, mounting specifications, and integration requirements in your technical documentation. Comprehensive specifications minimize misunderstandings and design iterations.

Intellectual Property Protection

Establish clear intellectual property agreements covering design ownership, confidentiality requirements, and technology transfer limitations. Proper IP protection ensures business advantage preservation.

Consider trademark protection and design patents for unique features or applications. Professional legal consultation helps establish comprehensive IP protection strategies.

Development Timeline Management

Establish realistic development timelines, including design phases, prototype testing, and production ramp-up periods. Clear timelines enable better project management and resource allocation.

Build in contingency time for design modifications, testing iterations, and certification processes. Realistic scheduling reduces project stress and improves final product quality.

Quality Control Integration

Implement joint quality control procedures,s including design reviews, testing protocols, and acceptance criteria. Collaborative quality management ensures products meet specifications and performance requirements.

Establish regular review meetings and progress checkpoints throughout the development process. Continuous monitoring enables early issue identification and resolution.

Strategic Pricing and MOQ Negotiation Techniques

Volume-Based Pricing Strategies

Understand how order volumes affect pricing structures and negotiate volume discounts based on projected annual requirements. Larger commitments typically result in better pricing terms.

Consider consolidated ordering strategies that combine multiple product lines or applications to achieve better volume pricing. Strategic ordering can significantly reduce overall procurement costs.

Payment Terms Optimization

Negotiate favorable payment terms that balance cash flow requirements with supplier financial needs. Consider options like partial advance payments, milestone-based payments, or letter of credit arrangements.

Explore early payment discounts or extended payment terms based on order volumes and partnership development. Flexible payment arrangements can provide additional value beyond base pricing.

Long-Term Contract Benefits

Develop long-term supply agreements that provide pricing stability and supply security. Multi-year contracts often include annual volume commitments in exchange for guaranteed pricing and capacity allocation.

Include clauses for technology updates, capacity expansion, and performance improvements in long-term agreements. Forward-looking contracts protect against market volatility and ensure continuous improvement.

MOQ Optimization Strategies

Understand the manufacturer's production economics and work together to optimize minimum order quantities. Consider seasonal ordering patterns or inventory management strategies to meet MOQ requirements efficiently.

Explore partial shipment options or inventory holding agreements that allow smaller individual orders while meeting overall MOQ requirements. Creative logistics solutions can provide ordering flexibility.

Comprehensive Factory Evaluation and Quality Assurance Protocols

Production Facility Assessment

Conduct thorough factory audits for wall mounted battery covering production equipment, quality control systems, and workforce capabilities. Modern automated production lines indicate manufacturing sophistication and quality consistency.

Evaluate the facility's cleanliness, organization, and maintenance standards. Well-maintained facilities typically produce higher quality products and demonstrate professional management practices.

Quality Control System Evaluation

Review testing equipment, calibration procedures, and quality control documentation systems. Comprehensive testing capabilities ensure product reliability and performance consistency.

Examine quality records, defect tracking systems, and corrective action procedures. Systematic quality management indicates commitment to continuous improvement and customer satisfaction.

Environmental and Safety Compliance

Assess environmental management systems, waste disposal procedures, and safety protocols. Responsible manufacturers implement comprehensive environmental and safety management systems.

Review compliance with local environmental regulations and international environmental standards. Environmental responsibility indicates corporate maturity and sustainability commitment.

Workforce and Management Evaluation

Evaluate workforce skills, training programs, and management systems. Skilled workers and systematic training programs contribute to product quality and production efficiency.

Assess management communication skills, technical expertise, and problem-solving capabilities. Strong management teams provide better partnership experiences and more reliable performance.

Identifying Leading Wall Mounted Battery Suppliers in 2025

Technology Leadership Indicators

Leading suppliers invest continuously in R&D and demonstrate technology leadership through product innovation and performance improvements. Look for manufacturers developing advanced BMS technology and energy density improvements.

Evaluate patent portfolios, research publications, and technology partnerships as indicators of innovation capability. Technology leaders typically offer more advanced products and better long-term competitiveness.

Market Presence and Customer Base

Established market presence across multiple industries and geographic regions indicates supplier reliability and adaptability. Diverse customer bases demonstrate versatility and market acceptance.

Review customer testimonials, case studies, and repeat business rates to assess customer satisfaction levels. Satisfied customers indicate reliable performance and good service quality.

Service and Support Capabilities

Comprehensive service capabilities, including technical support, training programs, and local service networks, distinguish leading suppliers from commodity manufacturers.

Evaluate response times, problem resolution capabilities, and ongoing support quality. Superior service capabilities ensure successful product implementation and long-term satisfaction.

Financial Strength and Stability

Financial stability enables suppliers to invest in technology development, capacity expansion, and service improvement. Stable suppliers provide better long-term partnership security.

Review growth trends, investment activities, and market expansion plans to assess the supplier's strategic direction and sustainability. Growing suppliers can provide expanding capabilities and services.

Conclusion

Selecting the right wall mounted battery manufacturer in China requires systematic evaluation across multiple dimensions, including technical capabilities, quality systems, certifications, and service support. The most successful partnerships emerge when buyers invest time in thorough supplier assessment, establish clear communication channels, and develop mutually beneficial long-term relationships.

Chinese manufacturers offer compelling advantages in terms of cost competitiveness, technological innovation, and production scalability. However, success depends on identifying manufacturers with proven track records, robust quality systems, and commitment to continuous improvement. The investment in proper supplier selection pays dividends through reliable product performance, responsive service, and sustainable business growth.

FAQ

Q: What certifications should I prioritize when selecting a wall mounted battery manufacturer?

A: Focus on IEC62619 for safety, UN38.3 for transportation, and ISO 9001 for quality management. Additionally, consider CE marking for European markets and UL certification for North American applications. These certifications ensure both product safety and market compliance.

Q: How can I verify a manufacturer's production capacity and quality consistency?

A: Request factory audits, review production line automation levels, and examine quality control documentation. Ask for customer references from similar applications and order sample products for independent testing. Automated production lines typically indicate better capacity and consistency.

Q: What should I expect for minimum order quantities and delivery times?

A: MOQs vary significantly based on customization levels, typically ranging from 10-100 units for standard products to 500+ units for fully customized solutions. Standard delivery times range from 2-4 weeks for stock items to 8-12 weeks for custom designs. Discuss specific requirements during initial negotiations.

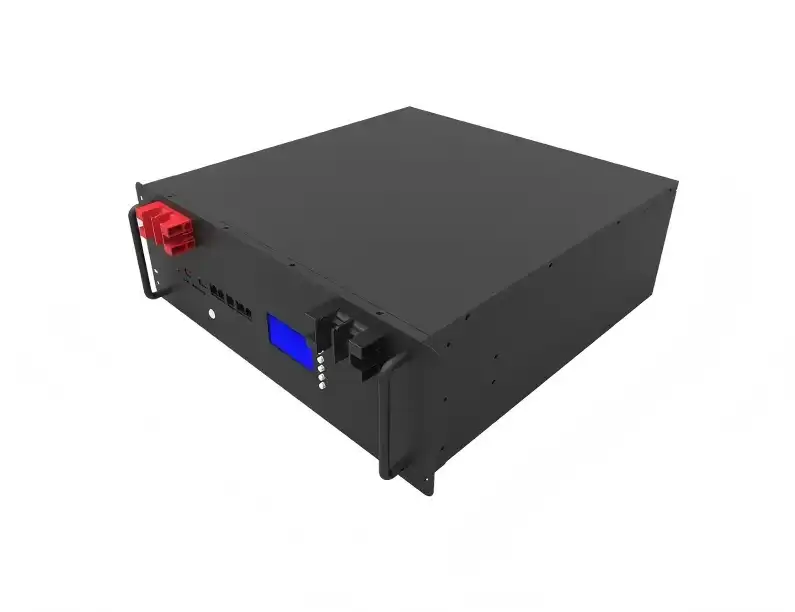

Partner with TOPAK for Reliable Wall Mounted Battery Solutions

TOPAK New Energy Technology combines 17 years of manufacturing expertise with advanced automated production capabilities to deliver superior wall mounted battery systems. Our in-house BMS development, comprehensive certifications, and global distribution network spanning 15+ countries ensure reliable performance and responsive support. As an established wall mounted battery manufacturer, we provide fully customizable solutions backed by rigorous quality control and technical expertise. Ready to discuss your energy storage requirements? Contact us at B2B@topakpower.com for personalized consultation and competitive quotations.

References

1. Global Energy Storage Market Report 2024, International Energy Agency

2. Lithium Battery Manufacturing Standards and Best Practices, IEEE Standards Association

3. China's Battery Industry Development and Export Analysis, China Chemical and Physical Power Sources Industry Association

4. Quality Management Systems in Energy Storage Manufacturing, International Organization for Standardization

5. Safety Requirements for Lithium Battery Systems in Industrial Applications, International Electrotechnical Commission

6. Global Supply Chain Analysis for Energy Storage Components, Bloomberg New Energy Finance