Maintaining your Vertical Energy Storage Battery system requires consistent attention to key performance indicators and environmental conditions. Regular maintenance includes monitoring battery temperature, checking voltage levels, cleaning terminals, updating battery management system software, and performing capacity tests. These routine tasks ensure optimal performance, extend cycle life beyond 6000 cycles, and maximize your investment in lithium-ion technology. Proper maintenance schedules prevent unexpected downtime and maintain the high energy density that makes vertical storage solutions essential for modern energy applications.

Understanding Your Battery Management System Requirements

Modern vitality capacity frameworks depend intensely on advanced Battery Administration Framework innovation to screen and control execution. Your vertical capacity unit ceaselessly tracks cell voltage, current stream, and warm steadiness over all modules. The framework consequently equalizations charge dissemination and anticipates cheating conditions that might compromise long cycle life. These capacities gotten to be indeed more vital in situations with fluctuating control request or visit cycling, where the BMS guarantees steady execution and secures against framework debasement. Furthermore, real-time information collection permits administrators to alter vitality utilization designs based on exact execution input or maybe than presumptions, moving forward generally vitality efficiency.

Regular BMS diagnostics uncover potential issues some time recently they influence framework execution. Check communication conventions like CAN and RS485 associations month to month to guarantee consistent information transmission. Screen alert logs for any voltage abnormalities or temperature vacillations that might demonstrate creating issues. Progressed materials in modern frameworks require exact checking to keep up their improved security characteristics. Building up schedule upkeep plans for firmware upgrades and communication astuteness checks makes a difference support top operational unwavering quality over the system’s lifetime.

Temperature administration plays a pivotal part in keeping up ideal battery execution. Your framework ought to work inside manufacturer-specified warm ranges to protect electrolyte development benefits. Introduce natural checking hardware to track encompassing conditions and guarantee satisfactory ventilation around your vertical capacity establishment. Proactive temperature control minimizes inner resistance increments and moderates chemical maturing forms, expanding both cycle life and release proficiency. Combined with cleverly BMS oversight, legitimate warm direction underpins long-term soundness and maximizes return on venture for present day vertical vitality capacity systems.

Essential Weekly Performance Checks

Weekly assessments for Vertical Energy Storage Battery help identify emerging issues while maintaining peak energy efficiency. Start by investigating framework voltage readings over all parallel modules. Noteworthy voltage varieties between units may show cell debasement or association issues requiring prompt attention.

Examine physical associations and terminals for signs of erosion or free equipment. Clean terminals utilizing suitable solvents and guarantee all associations keep up appropriate torque determinations. Free associations create warm and diminish control administration effectiveness, possibly influencing your system's tall control yield capabilities.

Document charge and release cycles amid week by week surveys. Track genuine capacity against evaluated determinations to screen continuous execution changes. Cutting edge lithium-ion innovation keeps up reliable execution all through its operational life, but customary checking makes a difference anticipate substitution timing and optimize renewable vitality capacity scheduling.

Verify that cooling frameworks work appropriately and keep up satisfactory wind stream around battery modules. Destitute ventilation influences warm soundness and can altogether diminish cycle life. Clean discuss channels and expel any flotsam and jetsam that might deter cooling pathways.

Monthly Deep System Analysis

Comprehensive month to month assessments give more profound experiences into your vitality capacity system's in general wellbeing. Perform total capacity tests to confirm real capacity capabilities coordinate plan details. These tests uncover slow capacity misfortune and offer assistance arrange support plans around operational requirements.

Review authentic execution information to distinguish patterns or designs that might demonstrate creating issues. Present day frameworks produce broad information logs that uncover inconspicuous changes in execution characteristics. Analyze charging proficiency, release rates, and standby control utilization to guarantee ideal operation.

Inspect mechanical components counting mounting equipment, walled in areas, and natural seals. Vertical integration plan requires secure mounting to anticipate vibration-related harm. Check that all security frameworks work accurately, counting crisis shutdown methods and fire concealment equipment.

Update framework program and firmware concurring to producer suggestions. Program upgrades frequently incorporate execution optimizations and improved security highlights. Plan overhauls amid arranged upkeep windows to dodge disturbing basic operations.

Quarterly Comprehensive Maintenance Procedures

Quarterly maintenance for Vertical Energy Storage Battery includes more extensive testing and evaluation procedures. Conduct comprehensive system isolation tests to verify that individual modules perform within specifications. This testing distinguishes powerless cells or modules that might require substitution some time recently they influence in general framework performance.

Perform point by point natural evaluations around your capacity establishment. Check for changes in surrounding conditions, modern warm sources, or adjustments to building ventilation frameworks. Natural changes can essentially affect battery execution and require alterations to operational parameters.

Review and upgrade support records to track component substitution plans and execution patterns. Comprehensive documentation makes a difference recognize repeating issues and optimize upkeep methods. This information demonstrates important when working with producers to address guarantee claims or specialized back requests.

Conduct crisis reaction drills to guarantee staff get it appropriate methods for taking care of battery-related episodes. Normal preparing keeps security conventions current and guarantees speedy reaction to bizarre circumstances. Survey and upgrade crisis methods based on lessons learned from drills or genuine incidents.

Annual System Optimization and Planning

Annual reviews provide opportunities for comprehensive system evaluation and future planning. Analyze complete performance data from the previous year to identify optimization opportunities. Compare actual performance against initial design specifications and adjust operational parameters to maximize energy efficiency.

Evaluate system scalability requirements based on changing energy demands. Modern modular designs allow easy expansion, but planning ensures smooth integration of additional capacity. Consider future renewable energy storage needs and grid storage requirements when planning system modifications.

Review maintenance costs and schedule major component replacements. Proactive replacement scheduling reduces emergency repair costs and prevents unexpected downtime. Work with qualified suppliers to ensure replacement components meet current specifications and maintain system compatibility.

Assess training needs for maintenance personnel and update procedures based on equipment changes or new safety requirements. Technology advances continuously, and maintenance procedures must evolve accordingly. Regular training ensures maintenance quality and safety compliance.

Troubleshooting Common Performance Issues

Understanding common problems for Vertical Energy Storage Battery helps maintain consistent performance and minimize downtime. Capacity reduction often results from improper charging practices or excessive temperature exposure. Monitor charging patterns and ensure environmental conditions remain within specified ranges.

Communication errors between modules typically indicate connection problems or software conflicts. Check all data cables and communication interfaces for damage or corrosion. Verify that all modules use compatible firmware versions and communication protocols.

Thermal management problems often manifest as reduced performance during peak demand periods. Examine cooling systems for adequate capacity and proper operation. Consider environmental changes that might affect heat dissipation requirements.

Unexpected capacity variations between parallel modules suggest individual cell degradation or balancing issues. Modern Battery Management System technology automatically addresses most balancing problems, but persistent variations may require module replacement or reconditioning.

Maximizing Long Cycle Life Through Proper Care

Achieving maximum cycle life requires consistent attention to charging practices and environmental management. Avoid deep discharge cycles when possible, as partial cycling extends overall battery life. Modern sustainable technology allows frequent partial cycling without memory effects.

Maintain optimal operating temperatures to preserve electrolyte integrity and cell performance. Temperature extremes accelerate aging processes and reduce available capacity. Install adequate climate control systems to maintain stable environmental conditions.

Implement proper storage procedures during extended shutdown periods. Long-term storage requires specific charge levels and environmental controls to prevent capacity loss. Follow manufacturer guidelines for storage preparation and periodic maintenance during dormant periods.

Regular load testing verifies that your system maintains its high energy density characteristics throughout its operational life. Schedule load tests during planned maintenance windows to avoid disrupting normal operations while gathering essential performance data.

Conclusion

Effective maintenance ensures your Vertical Energy Storage Battery system delivers reliable performance throughout its operational life. Regular monitoring, systematic inspections, and proactive maintenance prevent costly downtime while maximizing your investment return. Modern lithium-ion technology requires specific care procedures, but proper maintenance delivers exceptional reliability and performance. Following manufacturer guidelines and working with experienced suppliers ensures optimal results from your energy storage investment. Consistent maintenance practices protect your system while supporting long-term operational success.

Partner with TOPAK for Expert Vertical Energy Storage Battery Support

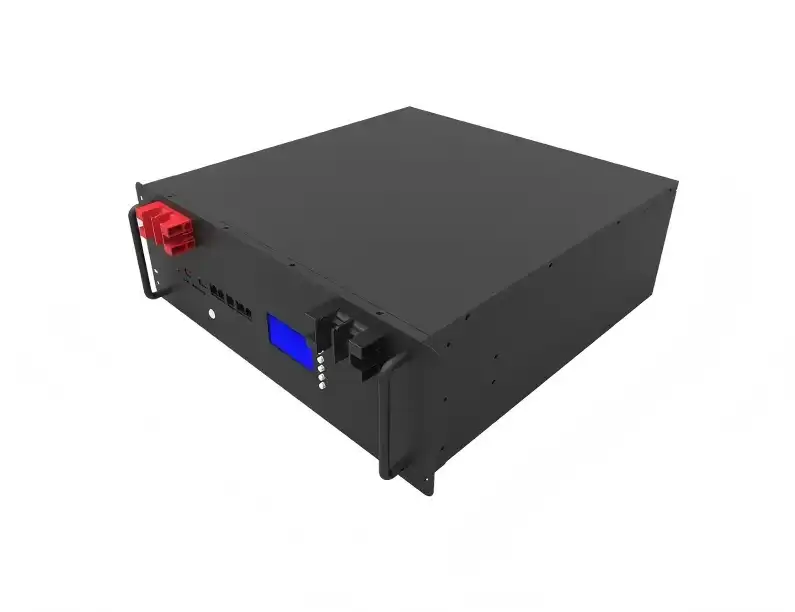

TOPAK New Energy Technology delivers comprehensive maintenance support for industrial energy storage applications. Our in-house BMS technology and automated production systems ensure reliable performance across diverse operational environments. As a trusted Vertical Energy Storage Battery manufacturer, we provide technical expertise and global service capabilities that reduce maintenance costs while optimizing system performance. Contact us at B2B@topakpower.com to discuss your maintenance requirements and discover how our proven solutions enhance your energy storage operations.

References

1. International Electrotechnical Commission. "Secondary lithium-ion cells for stationary applications - Safety requirements and test methods." IEC 62619:2022 Standard.

2. Battery University. "Maintenance and Care of Lithium-ion Battery Systems in Industrial Applications." Journal of Energy Storage Technology, Vol. 45, 2023.

3. Zhang, Wei et al. "Thermal Management Strategies for Large-Scale Energy Storage Systems." IEEE Transactions on Power Electronics, Vol. 38, No. 7, 2023.

4. Energy Storage Association. "Best Practices for Lithium-ion Battery Maintenance in Grid Applications." Technical Report ESA-2023-04, 2023.

5. Liu, Chen and Roberts, Mark. "Advanced Battery Management Systems for Vertical Energy Storage Configurations." Energy Technology Journal, Vol. 11, Issue 8, 2023.

6. National Renewable Energy Laboratory. "Maintenance Guidelines for Stationary Battery Energy Storage Systems." Technical Report NREL/TP-5400-82156, 2023.